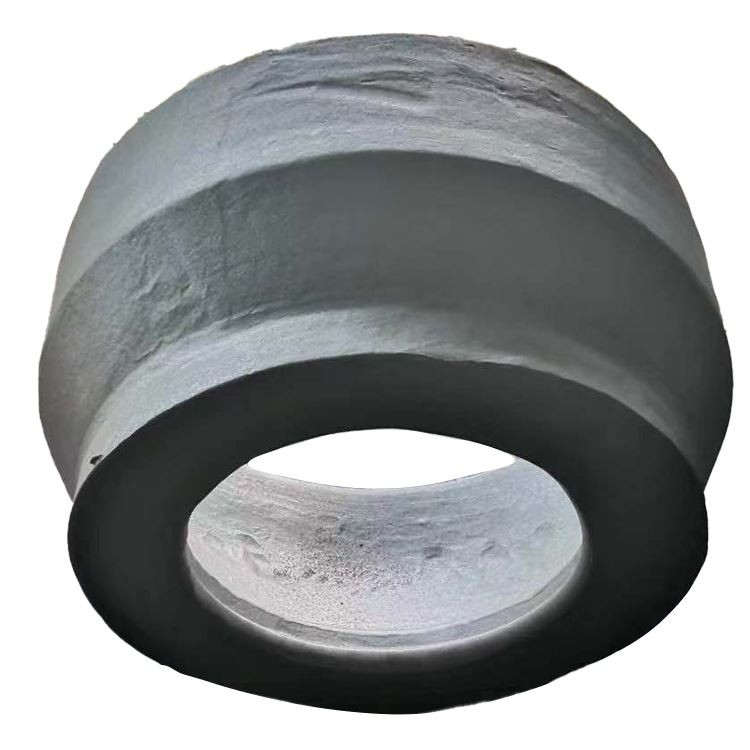

2618 Cov Khaub Ncaws Loj Tuag Forgings

Lub Zog thiab Kev Lag Luam Hluav Taws Xob yog ib qho tseem ceeb tshaj plaws rau lub zog, kev lag luam niaj hnub no yuav tsum tau ua kom muaj ntau yam kev xav tau ntau dua li lwm cov ntaub ntawv thiab cov ntaub ntawv feem ntau siv nyob rau hauv lub zog thiab hluav taws xob industry. They are lightweight, strong, corrosion-resistant, and have excellent thermal conductivity. These properties make them ideal for a wide range of applications, including turbine blades, generator components, and transmission line hardware.

1. Cov Khoom Siv Txheej Txheem & Cov Txheej Txheem Tsim Khoom

2618 Tus loj txhuas allolo aluminium yeej muaj kev kub siab aluminium (xws li 708), suav nrog ntawm npib tsib xee (ni) thiab hlau (FE) cov khoom siv ntws tawm ntawm cov khoom siv hluav taws xob ntau, cov yam ntxwv muaj txiaj ntsig zoo rau cov khoom siv hluav taws xob ntau dua thiab Cyclic Load tej yam kev mob. 2618 kev sib tw ntau, thiab lwm yam kev ntsuas pisting, thiab kev ua haujlwm siab} kev ua haujlwm siab.

Tseem Ceeb Alloying Ntsiab:

Tooj (Cu): {1.8-2.7% (lub zog ntxiv dag zog, cov qauv al₂cu)

Magnesium (mg): {1.3-1.8% (synergistically ntxiv nrog tooj liab, thiab cov ntaub mg₂si theem)

Nickel (NI): {{0.8-1.4% (txhim kho siab kub lub zog thiab ruaj khov, thiab lwm yam} 2}})

Hlau (FE): {{0.8-1.4% (txhim kho siab kub lub zog thiab ruaj khov, thiab lwm yam})

Silicon (si): {0.10-0.30% (ua kom zoo tshaj plaws cua sov kho)

Cov khoom siv hauv paus:

Aluminium (Al): Tshuav

Kev tswj kev impurities:

Zinc (Zn): 0.25% Max

Manganese (MN): 0.10% Max

Titanium (ti): 0.10% Max

Chromium (CR): 0.10% Max

Lwm cov ntsiab: 0.05% Max txhua, 0.15% Max tag nrho

Cov txheej txheem tsim khoom (rau kev tuag loj tsis nco qab): Kev tsim khoom ntawm 2618 loj tuag Forgings yog qhov rhiab heev rau kev ua kom sov, thiab kev kho kom sov siab, thiab lub zog kho cua sov thiab ruaj khov.

Cov Khoom Siv Raw Npaj Ua & Loj Loj Intots:

Kev ua tau zoo, tsis muaj mob loj yog xaiv cov qauv sib txawv, tsis muaj cov txheej txheem sib txawv ntawm cov khaub ncaws.

Ingots yuav tsum raug cov tshuaj ntsuam xyuas cov tshuaj ntsuam xyuas thiab tshuaj xyuas ultrasonic los xyuas kom meej cov xim hlau tsis zoo .

Multi-Pass Pre-Forging (chim siab thiab kos duab):

Cov loj agots feem ntau ua ntej dhau los ntau dhau kev chim siab thiab cov qauv ua ntej, thiab cov qauv sib dhos, thiab cov qauv sib dhos, thiab cov qauv sib dhos, thiab cov qauv sib dhos, thiab cov qauv sib xyaw nrog cov nyom sab hauv {}}

Pre-Forging yog nqa tawm ntawm loj hydraulic lossis roj nias, nrog kev tswj kom meej ntawm deformation kub thiab npaum li cas.

Txiav:

Billts yog precisely txiav raws li kev txiav txim siab ua ntej thiab kev lom zem zaum kawg.

Tso kev sov:

Cov khoom loj yog cov khoom sib txawv thiab maj mam muab rhaub kom muaj kev cuam tshuam rau cov qoob loo zoo nkauj (ntau yam kev faib tawm tshiab

Loj Tuag Forging Tsim:

Ib lossis ntau dua strikes / nias tau thov rau 10, {1} pons muaj ntau yam, thiab kev lom zem} Cov kab mob sib tw, kom muaj kev lom zem nrog cov complex contour ntawm ib feem thiab ua tiav cov nyom shaping .

Stepwise forging: Rau cov khoom uas tsis tshua muaj neeg lossis cov khoom noj ntau heev, Forging yuav ua tau nyob rau hauv ntau daim tuag thiab cov kauj ruam kom maj mam sau cov duab kawg .

Ib leeg:

Tom qab forging, lub hnyav flash ib ncig ntawm periphery ntawm loj forging yog tshem tawm .

Kev Kho Cua Sov:

Kev Kho Kub Kho Kub: Cov kev zam loj yog rhuab hauv ib qho kev tswj hwm kom sov loj rau kev siv lub sijhawm ua kom zoo rau kev ua kom zoo nkauj {} Kev Kub Siab Tshaj Plaws

Quenching: Txias nrawm los ntawm kev daws qhov ntsuas kub. {{{1} {{1} {{1} {.

Kev Kho Mob Laus:

T61 Tauj: Qhov no feem ntau yog siv zuaj rau 2618, ua tiav los ntawm kev tswj hwm kev laus, xws li10-20 huab cua sov-kub ua tau zoo {}}

Loj Tensile / Csterpressation ntxhov siab nyem (E . g., T6151):

Tom qab quenching, loj sau cia feem ntau yuav tsum muaj kev ntxhov siab siv lub zog loj lossis cov cav tov sib zog ua kom muaj kev ntxhov siab ntau dua, thiab cov kauj ruam no yog qhov tshwj xeeb rau cov khoom loj; rau cov kev pab kub siab, seem kev ntxhov siab tuaj yeem cuam tshuam tus cwj pwm tsis sib haum thiab ua kom lub neej ua kom lub neej ua kom zoo.

Xov & Kev Soj Ntsuam:

Deburring, tua cov panening (txhim kho kev ua tsaug), txoj kev tshuaj xyuas kev ua kom ntev, cov tshev ua kom nto.

Thaum kawg, kev sim ua tsis zoo no zoo nkauj (e {. Cov khoom siv tam sim no) thiab cov khoom lag luam zoo tshaj plaws {}}

{{02.} cov khoom siv mechanical ntawm 2618 loj tuag kev lom zem

2618 Cov Qauv Kev Ua Yeeb Yam Loj Nyob rau hauv lub zog T61 tshwj xeeb, ua rau muaj kev xaiv kom nruj, thiab muaj txiaj ntsig zoo rau kev ua haujlwm ntev rau kev ua haujlwm ntev (L) Kev Taw Qhia .

|

Cov Hom Khoom |

T61 Tus nqi T61 (Chav Chav) |

Tus nqi T61 (250 Qib) |

Kev Ntsuas Cov Lus Taw Qhia |

Lub hom phiaj |

|

Qhov kawg tensile lub zog (UTS) |

430-470 mpa |

260-300 mpa |

L / lt / st |

ASTM B557 |

|

Paib zog (0.2% ys) |

380-420 mpa |

200-240 mpa |

L / lt / st |

ASTM B557 |

|

Elongation (2 nti) |

7-12% |

10-18% |

L / lt / st |

ASTM B557 |

|

Brinell hardness |

135-150 hb |

N/A |

N/A |

Astm E10 |

|

Qeeb zog lub zog (10⁷ Cycles) |

130-160 mpa |

100-120 mpa |

N/A |

ASTM E466 |

|

Lub zog nkag los ntawm lub zog (1000h, 250 degree, 0.2% hom) |

100-120 mpa |

N/A |

N/A |

ASTM E139 |

|

BLACTURE TAIS K1C |

20-26 mpa√m |

N/A |

N/A |

ASTM E399 |

|

Tawv muaj zog |

250-280 mpa |

N/A |

N/A |

ASTM B769 |

|

Elastic modulus |

72 GPA |

65 GPA |

N/A |

Astm E111 |

Cov khoom sib thooj thiab anisotropy:

Qhov loj thiab qhov hnyav ntawm kev tuag nyob sab hauv cov cuab yeej sib txawv, tshwj xeeb tshaj yog li cas los xij, kev kho kom sov siab tshaj plaws ua rau cov khoom siv cua sov siab tshaj plaws {2}

Meej meej grain flow tswj cov lus qhia zoo tshaj plaws hauv kev thauj khoom thiab luv luv-transverse anisotropy, tshwj xeeb rau cov chaw siab tshaj plaws hauv thaj chaw tseem ceeb hauv.

3.} microstructural yam ntxwv

Lub microstructure ntawm 2618 loj tuag lom zem yog qhov tseem ceeb ntawm nws qhov siab-kub lub zog, thiab qaug zog.

Qhov Tseem Ceeb Microstructural nta:

Ua kom zoo, hnav khaub ncaws, thiab cov qauv grain:

Tom qab chim siab thiab tuag forging nrog kev sib tw loj, thiab sib zog ua kom nruj, ua kom muaj zog, thiab cov roj sib zog, thiab qaug zog lub neej.

Ruaj khov dispersroids tsim los ntawm ni thiab FE EMENTS (e {{} pin}, yog li tswj tau zoo expectening {}}

Cov nplej nruam cov nplej tau yooj yim rau cov duab:

Qhov no yog qhov tseem ceeb tshaj plaws ntawm kev tuag nplua nuj {}} ua raws li cov khoom tuag loj thiab ua raws li cov txheej txheem sab nraud thiab sab hauv.

Cov nplej no ntws ua kom nruj nrog ntu kev daws teeb meem thawj zaug, cov kev sib txuas nrog qhov kev ntxhov siab, thiab kev tswj hwm loj} ntws yog qhov tseem ceeb heev rau txhua qhov kev ua yeeb yam ntseeg tau .

Kho kom tswj thiab kev faib cov khoom sib faib ntawm kev txhawb nqa theem ntxiv (precipitates):

Tom qab kev tswj hwm kev kho mob kub thiab kev laus, thawj zaug ua ke nrog kev sib xyaw ua ke nrog kev sib txuas, thiab cov khoom siv hluav taws xob sib txawv, morphology, thiab txuas.

Rau cov neeg loj 2618 Forgings, kev laus zog (T61 Tauj) muaj ntau yam kub thiab muaj kev sib txuam, yog li ua kom cov neeg nplua nuj nyob rau ntawm cov neeg nplua nuj ntev ntev ntawm cov neeg siv tshuab ntau dua thaum muaj kev kub ntxhov ntawm cov khoom kub siab thaum ub.

Siab metallurgical huv huv thiab tsawg tsis xws luag:

Kev Tuag Sib Tw Loj muaj cov qauv siv hluav taws xob tsis txaus ntseeg, yog li ua rau muaj kev tiv thaiv cov khoom siv hlau tsis zoo los ntawm 100% kev tshuaj xyuas rau sab hauv zoo .

4.} Qhov ntev tshaj tawm & kev thev taus

2618 Cov Khaub Ncaws Loj Cov Khaub Ncaws Tsis Txaus Siab yog siv rau cov chaw muaj kev sib tw nrog kev ua kom nruj thiab muaj peev xwm ua tiav thiab ze-net scess ntau.

|

Chaw ua uas tsis tau haus |

Raug loj npaum li cas |

Aerospace Forging Daus Siab (e . g .}}}, 11770) |

Precision Machining Divance |

Txoj kev xeem |

|

Max lub hnab ntawv qhov xwm txheej |

500 - 3000 hli |

± 0.5% lossis ± 2 hli |

{0.05 - ± 0.3 hli |

CMM / Laser Scan |

|

MIN Phab Ntsa Thickness |

5 - 100 hli |

± 1.0 hli |

{0.2 - ± 0.5 hli |

CMM / Thickness Tagsee |

|

Nta ntau |

20 - 500 kg |

±3% |

N/A |

Hluav taws xob nplai |

|

Nto Roughness (forged) |

Ra 12.5 - 50 μm |

N/A |

Ra 1.6 - 6.3 μm |

Profat |

|

Huv |

N/A |

0.5 hli / 100 hli |

0.1 hli / 100 hli |

Flawe Gauge / CMM |

|

Txoj kev sib tw |

N/A |

0.3 Qib |

0.1 Qib |

Lub ntsuas cua / cmm |

Lub peev xwm custom:

Kev tuag tuag tuag ntau feem ntau yog customized, tsim raws li cov qauv cad cov qauv thiab engineering muab los ntawm cov neeg siv khoom .

Cov tuam txhab tsim nyog yuav tsum muaj cov tuam txhab tuag muaj zog thiab tsim muaj peev xwm, nrog rau ultra-loj khoom {}}

Cov kev pabcuam tag nrho tuaj yeem muab tau, los ntawm cov khoom siv ua ntej, tuag forging, kev kho cua sov, ntxhov siab kom huv si / ua tiav machining tshuab.

5.}}}}} Kev Kho Mob Cua Sov

Cov khoom ntawm 2618 alloy yog siab heev rau kev kho cua sov, tshwj xeeb yog kev kho kom muaj kev sib tw thiab qhov tob ntawm kev kho cua sov.

|

Tauj Ntshav |

Kev piav qhia cov txheej txheem |

Cov Kev Siv Raug Raug |

Cov yam ntxwv tseem ceeb |

|

O |

Tag nrho anealed, muag muag |

Nruab Nrab Lub Xeev ua ntej kev ua haujlwm ntxiv |

Qhov siab tshaj plaws ductility, qis tshaj lub zog |

|

T61 |

Daws cov cua sov kho, ces muaj zog |

Kev Kub Siab Kub Txheej Txheem, Cov Khoom Siv Cav |

Qhov zoo tshaj siab-lub zog, chav nyob zoo-temp zog, nkees tsis kam |

|

T6151 |

Daws cov cua sov kho, artificialially muaj hnub nyoog, ncab kev ntxhov siab-relieved |

Rau kev txo qis kev ntxhov siab thiab machining distortion |

Qhov zoo tshaj plaws kub-kub lub zog, qis dua residual kev ntxhov siab |

Cov Lus Taw Qhia Txog Kev Xaiv Tsa:

T61 Tauj: Qhov no yog tus qauv thiab nyiam ua kom muaj zog rau loj 2618 Forgings, muab cov qaug zog, ua kom muaj kev qaug zog, thiab cua sov ntawm qhov kub siab .

T6151 Tauj: Rau tuab lossis precision-machined loj zam txim, yog tsis muaj tseeb rau kev tswj hwm kev ntxhov siab thiab txo cov kev ntxhov siab ntau ntawm qhov kub siab .

6. tshuab machining & Fabrication tej yam

Machining ntawm 2618 loj tuag Forgings feem ntau yuav tsum tau muaj cov cuab yeej txiav thiab cov txheej txheem ua kom zoo; nws weldability yog tsis zoo .

|

Kev phais |

Lub cuab yeej |

Pom zoo tsis |

Lus |

|

Txoj siav |

Carbide, PCD cov cuab yeej |

VC =100-500 m / min, f =0.1-1.0 hli / rev |

Siab Hardness, yuav tsum muaj cov cuab yeej siv tshuab hluav taws xob ntau ntau, kom pom tseeb rau saum npoo tiav |

|

Milling |

Carbide, PCD cov cuab yeej |

VC {=150-800 m / min, fz =0.08-0.6 hli |

Kev ua tau zoo machining chaw, ample cua txias, muaj ntau-axis tswj |

|

Kev drilling |

Carbide, coated hss |

VC =30-100 m / min, f =0.05-0.25 hli / rev |

Lub qhov sib sib zog nqus lub drilling, sab hauv txias, chip kev khiav tawm, nruj medensional tswj |

|

Tab tom |

Hss-e-pm |

Vc =5-20 m / min |

Lub cev siv hluav taws xob kom tsim nyog, tiv thaiv cov lus kua muag, xav txog kev txiav cov rog |

|

Vuam |

Tsis Pom Zoo (Kev Pom Zoo Vuam) |

Cov Khoom Loj 2618 Cheebtsam Muaj Weldability tsis zoo, nquag tawg thiab ua lub zog poob |

Thawj feem ntawm cov tshuab nyiaj ceev los yog brazing / diffusent sib koom (cov ntawv thov tshwj xeeb) |

|

Kev Kho Mob Realual Kev Kho Mob |

Tom qab kev kho kub-kub ua ntej-ncab / ua ntej-compression, lossis vibratory kev ntxhov siab, lossis kev hloov pauv ntawm stepwise machining |

Tiv thaiv machining distortion, kom pom kev ruaj khov, tshwj xeeb cuam tshuam rau kev ua haujlwm kub- |

Qhov txheej txheem tseem ceeb hauv nkoj

|

Kev Taw Qhia Fabricance:

Luam ntawv: 2618 hauv T61 npau taws muaj qhov nyuaj; nws lub tshuab luam ntawv yog qhov zoo tab sis rhiab rau twj hnav . cov cuab yeej loj, muaj lub zog loj, high-rigidity tshuab hluav taws xob yuav tsum tau .

Residual kev ntxhov siab: Cov kev lom zem loj muaj kev ntxhov siab tom qab quenching {}} kev ua kom muaj zog ntawm cov loj, suav nrog kev siv tshuab hluav taws xob ntau dua ua haujlwm .

Hwj txwv: PaStional Fusion Weldability ntawm 2618 Alloy yog heev tsis zoo, thiab tsis haum rau kev sib tw vuam (thiab tsis haum rau kev ntsuas kev sib tw Zuag qhia tag nrho cov kev ua kub kub .

{{07. corrosion Kuj & Kev Tiv Thaiv Cov Tshuab

Cov corrosion tsis kam ntawm 2618 loj aluminium aluminium aluminium aluminium aluminium alloy tuag kev nplua nuj, tshwj xeeb hauv kev tiv thaiv lossis cov tshuaj tiv thaiv ntxiv.

|

Corrosion hom |

T61 (Raug) |

Kev Tiv Thaiv Txheej Txheem |

|

Atmospheric corrosion |

Zoo |

Anodizing, lossis tsis muaj kev tiv thaiv tshwj xeeb xav tau |

|

Dej hiav txwv corrosion |

Tswj kav |

Anodizing, Kev Ua Tau Zoo Txheej Txheem, Galvanic Kev rho tawm |

|

Kev ntxhov siab corrosion cracking (SCC) |

Muaj ntsis rhiab |

Anodizing, txheej, seem kev ntxhov siab txo qis |

|

Exfoliation corrosion |

Muaj ntsis rhiab |

Anodizing, Txheej |

|

Intergranular corrosion |

Muaj ntsis rhiab |

Kev Kho Cua Sov |

Corrosion Tiv Thaiv Cov Tswv Yim:

Alloy thiab npau taws xaiv: Cov ntsiab lus tooj liab ntawm 2618 Alloy ua rau nws cov kev lag luam tsis zoo rau 6 xxxx seconds, tab sis qhov kev lag luam no feem ntau yog txais kom ua tiav qhov kev kawm kub siab {4}

Nto Kho:

Txoj kev: Cov qauv kev tiv thaiv thiab kev tiv thaiv zoo, sib sau ua yeeb yam dej ntws, txhim kho kev ua kom loj thiab cov txheej txheem tswj tau yog qhov tseem ceeb .

Kev Siv Tshuaj Conversion Coneings: Pab raws li cov cim tau zoo rau cov xim thav duab lossis cov nplaum, muab kev tiv thaiv corrosion ntxiv .

Cov Khoom Siv Ua Haujlwm Siab Txheej Txheej: Ntau-txheej kev ua haujlwm siab tiv thaiv kev tiv thaiv corrosion, tshwj xeeb tshaj yog nyob rau hauv cov cheeb tsam kub tshaj tawm {}}

Galvanic Corrosion Kev Tswj Xyuas: Thaum sib cuag nrog cov hlau tsis sib xws (e {{{}, rasonts, cov pa taws, uas yog qhov tshwj xeeb hauv cov teeb meem galvanic {}}

{{08. Cov Khoom Siv Rau Lub Cev Rau Cov Kws Tsim Khoom Lag Luam

Lub zog ntawm lub cev ntawm 2618 loj aluminium aluminium willing forging yog cov ntsiab lus nkag rau cov ntaub ntawv hauv kev ntsuas kub.

|

Ntiag tug |

Tus nqi |

Tsim Kev Txiav Txim Siab |

|

Ceev |

2.76 g / cm³ |

Lub Hnav Txom Nyem |

|

Melting ntau |

530-630 degree |

Kev Kho Cua Sov Thiab Vuam Qhov Rooj |

|

Thermal conductivity |

160 W/m·K |

Kev tswj hwm cua sov, kub dissipation tsim |

|

Hluav Taws Xob Kev Tshaj Tawm |

36% IACs |

Hluav Taws Xob Hluav Taws Xob |

|

Cov cua sov tshwj xeeb |

920 J / Kerg · K |

Thermal Mass thiab cua kub muaj peev xwm |

|

Thermal Expansion (CTE) |

22.8 ×10⁻⁶/K |

Kev hloov sab nraud vim yog qhov kub hloov pauv |

|

Cov tub ntxhais hluas lub modulus |

72 GPA |

Deflection thiab stiffness suav |

|

Poisson tus piv |

0.33 |

Cov Txheej Txheem Ntsuam Xyuas Parameter |

|

Damping muaj peev xwm |

Qi |

Kev co thiab suab nrov tswj |

Kev txiav txim siab tsim:

Kev kub siab lub zog kub thiab ruaj khov: 2618 lub zog khaws cia nyob rau hauv {{1}℃Kub ntau ntau yog ntau zoo dua rau lwm tus ua kom tau txais txiaj ntsig zoo .

Zoo heev qaug zog thiab creep resistance: Cov txheej txheem forging ua ke nrog cov yam ntxwv zoo li cov yam ntxwv ua rau nws haum rau cov cav sib xyaw kom haum rau cov cua txias kom ruaj khov rau cov cua sov {}}

Ultimate lub zog-rau-hnyav piv (ntawm qhov kub siab): Muab kev piv rau lub zog zoo tshaj plaws hauv kev ua haujlwm siab dua thiab muaj qhov hnyav ua tiav thiab kev siv hluav taws xob txo qis hauv Aero-engines.

Kev sib xyaw ua ke ntawm cov duab loj: Kev sib tuag tuag tuaj yeem tsim cov khoom siv nyob ze thoob-netometries, kev sib xyaw ua ke ntawm cov txheej txheem ntawm aero-engines.

Residual kev tswj hwm kev tswj hwm: Tswj cov kev ntxhov siab uas muaj kev ntxhov siab loj nyob rau hauv kev tsim qauv loj yog qhov tseem ceeb hauv kev tsim thiab kev sib luag, cuam tshuam nrog kev coj kom ruaj khov thiab kev kub ntxhov.}

Kev txwv tsis muaj kev txwv:

Tus nqi siab: Cov khoom siv Raw, kev txhim kho tus nqi, Forging cov peev peev nyiaj, thiab cov khoom siv kub heev, ua rau nws cov ntawv thov thoob plaws {}}

Ntev mus ua voj voog: Tus qauv tsim thiab tsim khoom ntawm cov tuag rau cov loj forgings thiab kev kho cua sov kom zoo nkauj .

Pluag weldability: Cov kev sib tw fusion vuam cov hau kev feem ntau tsis siv rau 2618 cov ris nra loj-{2}}

Qis chav-kub tshaj 7xxx koob: Nws chav-kub lub zog tsis yog li ultra-high-zog alloys zoo li 7075, tab sis nws zoo dua li tseem ceeb ntawm qhov kub siab .

Kev Lag Luam thiab Kev Txiav Txim Siab:

Daim ntawv thov muaj nqi siab: Ntau28 Forgings yog siv nyob rau hauv cov tswv yim Aerospace uas tsis tshua muaj nuj nqis txhim kho thiab kev nyab xeeb ntawm kev ua tau zoo thiab kev nyab xeeb cov npoo lawv muab.

Khoom Siv Khoom Siv Efficiency: Advanced nyob ze-Net nyeem ntawv forging kev siv tshuab thiab precision machining tau ua kom cov khoom loj, machining pub tseem yuav yog ntau.

Ib puag ncig ua phooj ywg: Alloys Alloys muaj kev hloov kho siab heev, ua kom haum nrog kev tsim khoom ntsuab thiab nce qib kev lag luam {}}

Txhim kho kev nyab xeeb: Kev ua yeeb yam zoo tshaj plaws ntawm kev quav ntsej muag ncaj qha rau cov khoom muaj kev nyab xeeb zoo li Aero-tshuab, uas yog qhov siab tshaj plaws ntawm lawv tus nqi.

Cim npe nrov: 2618 Cov Khaub Ncaws Kev Tuag Loj Ua Lus Pom Zoo, Tuam Tshoj 2618 Cov Khaub Ncaws Loj Ua Lus Sib Tuag, cov chaw muag khoom, Hoobkas

Xa kev nug