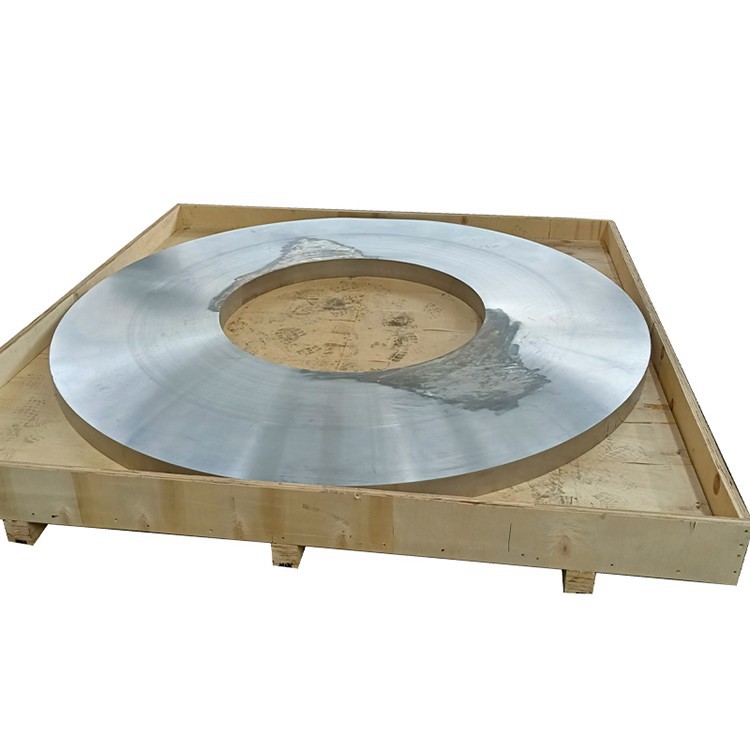

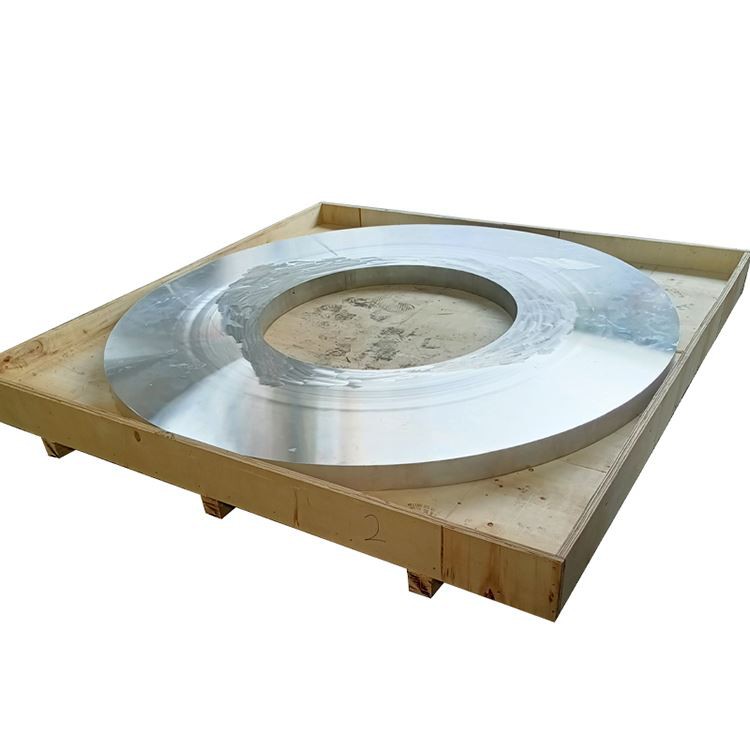

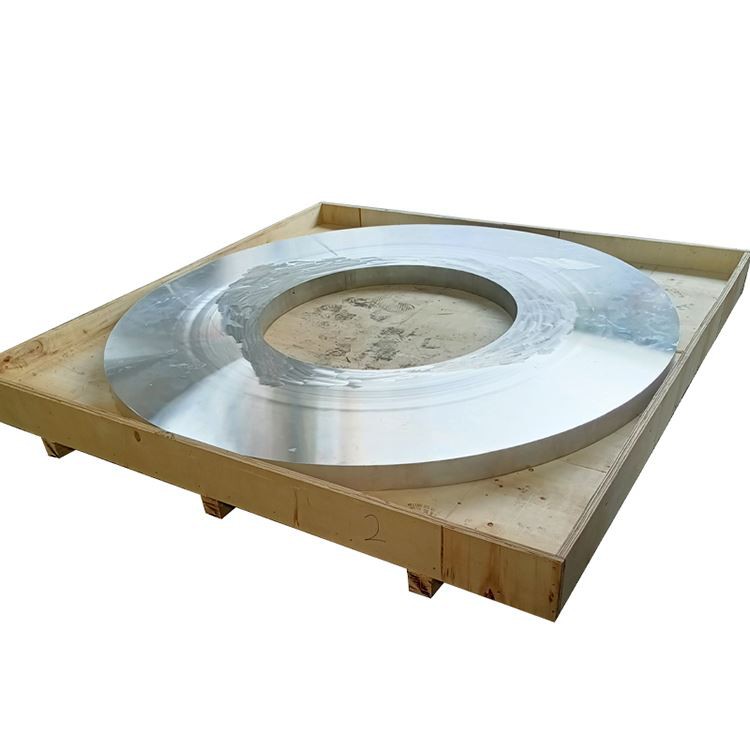

Thooj Loj Thiaj Walled Aluminium Forged Ntiv Nplhaib

Lub voj voos loj ntawm cov plaub hau Forging ntiv nplhaib, raws li cov neeg muaj txuj ci tseem ceeb, muaj kev tiv thaiv kev ua tub rog, thiab kev ua haujlwm ntawm kev ua. Nws adopts ua rau fasing technology thiab yog precances tsim los ntawm ntau cov txheej txheem, uas tuaj yeem ua tau ntau yam kev ua haujlwm thiab xav tau cov ntawv thov.

Cov khoom lag luam

1. Cov Khoom Siv Txheej txheem cej luam & Cov Txheej Txheem Tsim Khoom

Qhov loj tshaj txoj kab uas muaj kev lag luam thiab cov khoom siv tsis zoo, ua kom muaj zog tshaj plaws, tsis muaj zog, kev ruaj khov stability, thiab lub teeb ci ntsa iab. Piv rau dog dig aluminium ib ncig, cov yam ntxwv ntawm "tuab-ntsa" thiab muaj peev xwm tswj hwm, thiab muaj peev xwm tswj hwm cov khoom siv kub, thiab muaj peev xwm tswj hwm cov khoom siv kub.

Cov qib txhuas alloible: Cov cheeb tsam loj uas muaj cov nplhaib tau muab cov kev xav tau tshwj xeeb rau cov teebmeem kev nyuaj thiab rhiab heev kom tuab.

Ultra-siab zog lub zog alloys (piv txwv li, 7050, 7075, 20049, 2024): Cov alloys tswj lub zog siab thiab cov khoom siv tawv tawv txawm tias muaj qhov zoo tshaj plaws rau lawv, feem ntau yog siv hauv aerospace, kev tiv thaiv, thiab cov khoom siv siab.

High corrosion resistant \/ cryogenic alloys (piv txwv li 5083, 5A06): Hauv marine engineering, cryogenic cia tso tsheb hlau luam, thiab cov khoom siv siab loj, cov alloys loj heev, cryogenic nyuaj, thiab weldability.

General siab zog alloys (piv txwv li 6061, 6082): Siv rau cov qauv kev lag luam dav dav yuav tsum muaj lub zog loj dua thaum ntsuas tau zoo machinability thiab tus nqi.

Cov Txheej Txheem Forging Forging Rau Txoj Kab Loj Loj Loj-Walled Rings: Ua cov ciaj loj loj loj-ntsa aluminium forged rings yog ib qho nyuaj tshaj plaws cov haujlwm hauv Aluminium Forging. Qhov nyuaj ntawm cov txheej txheem tswj cov lus dag hauv kev ua kom covlub tsev zoothiabKev sib xyaw ntawm cov khoomHauv cov ntu sau ntawv zam txim:

Yaj thiab ingot npaj:

Lub siab tshaj plaws Purity thawj cov thawj coj ntawm thawj cov thawj coj thiab cov khoom siv tau xaiv los ua kom meej meej cov qib sib xyaw ua ke thiab tsis tshua muaj pes tsawg leeg.

Qhov tseem ceeb tshaj plaws, ua kom zoo nkauj, lim, cov ntsiab lus zoo nkauj heev thiab muaj hluav taws xob tsis muaj zog thiab cov hluav taws xob tsis muaj kev sib xyaw ua ke tsis pub dhau los yog cov hws khov.

Ultra-loj txoj kab uas loj thiab qhov hnyav hnyav yog tsim kev siv cov loj-ntawj txias (DC) casting tshuab. Txheej txheem casting yuav tsum tau kho kom haum tswj cov kev sib tw ntawm cov kev sib tw thiab cov qauv sib txawv, cov qauv sib cais, cais cais tawm.

Kev Kho Mob Homogenization:

Giant Ingots foro-ntev (feem ntau yog pua lub sijhawm), ntau theem, muaj ntau hom kev kho mob annealing kho. Lub hom phiaj yog ua rau pom cov macrosegration loj thiab cov teeb meem dendritic kev sib txawv, thiab txhim kho kev sib txawv ntawm cov khoom siv rau tom qab loj forging, txo txoj kev pheej hmoo ntawm kev tawg.

Billet npaj thiab tshuaj xyuas:

Lub ingot nto undergoes tob huv (hnyav tawv taub hau lossis milling hnyav lossis milling) kom huv si tshem tawm tej yam tsis xws luag thiab sib cais sab nraud.

Ua ntej kev zam, lub ingot undergoes 100% muaj txhij txhua, siab daws teeb meem ultrasonic siab. Rau cov ntaub falled forging ncaws pob, kev tshuaj ntsuam cov kev xav tau raws li tus qauv Aerospace siab tshaj plaws (piv txwv li Arp 1924 qib A), kom tsis muaj qhov tsis xws luag sab hauv.

Preheating: lub ingot lossis preform yog uniformly unleed rau cov forging ua kom sov. Txog cov tuab ntawm phab ntsa, lub sijhawm preheating ntev ntev yog kom ntseeg tau tias muaj qhov sib txawv ntawm cov nplaim thiab cov tub ntxhais uas tuaj yeem ua rau tawg.

Forging Sequence (Tseem Ceeb Rau Los Ntawm-Thickness Deformation Thiab Grain Flow Contrormation):

Siv cov khoom siv loj: Hnyav hydraulic nias tshaj li kaum txhiab tons (txawm tias kaum ntawm ntau txhiab lub taub hau me me, ua kom cov tub ntxhais loj, ua kom cov tub ntxhais muaj kev cuam tshuam nrog tag nrho cov khoom tawg.

Chim siab thiab kos duab: Lub Ingot undergoes ntau qhov kev qhia, ntau yam chim siab thiab kos duab rau ntawm cov xovxwm hydraulic. Qhov no tsis tsuas yog ua txhaum rau cov qauv txheej txheem tab sis kuj ua kom pom tseeb ntawm cov tub sab, tshem tawm cov tseem ceeb hauv porosity thiab macršregation, thiab kev tsim cov peliminary grain txaus.

Tho: Ib qho qauv ua ntej txhua lub sijhawm ua ntej yog tsim los ntawm tho nrog cov tuag loj thiab mandrels. Cov txheej txheem no ntxiv cov khoom siv ntxiv, kho microstructure, thiab pib coj cov grain txaus.

Ntiv nplhaib dov tsim (cov txheej txheem tseem ceeb): Ua tiav ntawm ultra-loj uas hlavov ntiv nplhaib dov machine. Ntiv nplhaib dov yog tshwj xeeb yog qhov tseem ceeb rau cov nplhaib tuab vim tias nws siv cov hmoov av zoo nkauj, ua kom cov nplej uas muaj txiaj ntsig zoo ib yam nkaus ntawm txoj kev ncig. Qhov no tseem ceeb heev rau kev txhim kho lub zog ua lub zog, qaug zog lub neej, thiab pob txha tawv tawv ntawm cov nplhaib tuab tuab tuab tuab. Lub nplhaib dov ib feem ntau koom nrog ntau qhov kev hla dhau los kom ntseeg tau tias muaj kev cuam tshuam zoo thiab tiv thaiv kev cuam tshuam hauv nruab nrab.

Tsawg kawg nkaus txo tus piv: Rau cov tuab falled forgings, tag nrho cov kev sib cais tag nrho yog yuav tsum tau ua kom tiav ntau dua li cov qauv kev zam txim, thiab tsim ntawm optimized, kho cov nyom txaus.

Kev Kho Cua Sov:

Kev kho cov tshuaj kho thiab quenching: Thaum daws cov kev kho mob tuab-walled forgings, nws yog qhov tseem ceeb los xyuas kom muaj qhov kub thiab txias nyob rau ntawm tag nrho cov ntu thiab soaking soaking. Quenching yog qhov kev sib tw loj tshaj plaws, yuav tsum muaj cov peev xwm txias muaj zog, polymer quenching, ua ib qho kev sib tw tsis zoo, ua ib qho kev sib txuam zoo li cov khoom siv. Txhua yam tsis muaj khaub ncaws tsis zoo lossis tsis txaus ntseeg yuav ua rau muaj kev cuam tshuam loj heev.

Kev Kho Mob Laus: Ib theem ib theem lossis ntau theem khoom muaj kev laus yog ua raws nyob ntawm qib alloy. Rau 7xxx series tuab-walled forgings, T74 kev kho mob me me rau kev hloov pauv me me, thaum tswj hwm siab bacture todleight.

Residual ntxhov siab nyem: Realive kev nyuaj siab hauv txoj kab uas loj loj faiks tom qab quenching siab heev. Hais txog kev ntsuas kev ntsuas xws li ncab (TXUPRESSING (TXUC51), Compression (TXU)

Xov & Kev Soj Ntsuam:

Tom ntej kho cov tshuab machining (roughing, semi-tiav) yog ua kom tshem tawm cov npoo av ruaj khov thiab ua kom ntseeg tau qhov tseeb.

Thaum kawg, cov teeb meem feem ntau tsis ua haujlwm thiab cov tshuaj ntsuam xyuas microstructural tau ua rau cov khoom lag luam siab tshaj plaws thiab cov neeg siv khoom yuav tsum tau ua.

2. Cov Khoom Siv Cov Tshuab Loj Ntawm Cov Thooj Loj Thies-Walled Txhuas Txhuas Forged Rings

Cov cuab yeej siv ntau yam ntawm txoj kab uas loj loj-walled txhuas forged rings yog cov cim tseem ceeb ntawm lawv txoj kev ntseeg tau. Ua tsaug rau kev lees paub thiab cov txheej txheem kho cua sov, lawv tswj tau cov khoom zoo heev txawm tias hauv cov nplooj tuab:

|

Cov Hom Khoom |

Kev Qhia Ua Tau Zoo |

Cov kom zoo dua ntawm cov tuab-walled forgings |

|

Siab zog khaws cia |

Tsawg kawg ntawm qhov sib txawv ntawm cov tub ntxhais thiab lub zog saum npoo hauv cov phab ntsa loj |

Kev zam txim zoo, muaj kev lom zem ntau, optimized los ntawm-tuab nyhuv |

|

BRACTENE HWJ HWJ |

Tswj cov txiaj ntsig siab K1c txawm txawm nyob hauv cov tuab tuab, txhim kho kev puas tsuaj rau siab |

Ntuab microstructure, cov nplej zoo, ua kom meej tswj hwm nag los yog faib |

|

Superior qaug zog |

Kev qaug zog ntev lub neej thiab cov nkees nkees nkees loj hlob tus nqi |

Grain fleet tau ua raws li lub nplhaib lub nplhaib ntawm ib ncig, tsis muaj cov tsis xws luag |

|

Kev nyuaj siab kev ntxhov siab corrosion (SCC) tsis kam |

Tshwj xeeb tshaj yog 7xxx Series T73 \/ T74 Tempers ua tau zoo tshaj plaws hauv ntu tuab |

Meej tshaj txhawb kev kho mob, zoo tshaj plaws kev ntxhov siab |

|

Kev tswj hwm anisotrotropy |

Odfracferential Oppripforial (tangential) thaj chaw, me me thiab tswj kev sib txawv hauv cov khoom radial thiab axial |

Ntau qhov kev coj ua forging thiab lub nplhaib dov kom paub tseeb tias niaj hnub uas cov nplej ntws hauv txhua qhov kev qhia |

|

Cryogenic Tougness |

5xxx series tuav tau zoo heev kev sib zog ntawm tsis kub heev |

Haum rau Cryogenic Ua Kua Ntim thiab Kev Siv |

Cov kev ua tau zoo tshaj plaws (nyob ntawm alloy thiab npau taws):

Qhov kawg tensile lub zog: 300 mpa - 600 mpa mpa

Tos lub zog ({0. 2%): 200 mpa {3}} mpa mpa mpa

Elongation: 7% - 18%

Hardness: 80 hb - 180 hb

Qaug zog dag zog (5 × 10⁷ mus): 100 mpa {3}} mpa mpa

BRACTURE TOFLESS (K1C): 25 mpa√ {2}} mpa√ mpa-mpa√ zoo dua li ua rau muaj cov phiaj xwm sib piv)

Cov Khoom Siv Khoom Ntawm Cov Khoom Siv:

Ib qho tseem ceeb tshaj plaws ntawm txoj kab uas loj uas muaj kev zam txim rau ntawm cov khoom ntiag tug (los ntawm saum npoo ntawm cov tub ntxhais kawm ntawv (los ua tsaug rau cov txheej txheem tshwj xeeb thiab kev tswj hwm. Cov tub ntxhais-rau-nto hardness txawv yog feem ntau tswj tsis pub dhau 5 HB.

Residual kev ntxhov siab feem ntau yog txo qis los ntawm TXX51 \/ TXX52 kev kho kom ntseeg tau tias machining ruaj khov thiab txhim kho scc tsis kam.

3. Microstration cov yam ntxwv

Lub microstructure ntawm loj loj-ntsa txhuas-walled aluminium forged rings yog qhov tseem ceeb ntawm kev sib xyaw thiab qhov ceev ntawm cov nplej thiab precipitates hauv cov tuab.

Qhov Tseem Ceeb Microstructural nta:

Siab rau forged-los ntawm grain qauv thiab lis dej ntws:

Ua tiav kev tshem tawm ntawm coarse yog-cam khwb cia nplej thiab dendritic cais, sib sau zoo, sib npaug, tsis sib xws cov nplej raws li kev coj ua tsis zoo.

Grainow Flow: Thaum muaj ntau hom kev forging thiab lub nplhaib dov, cov qauv hlau txuas nrog cov nplhaib sib txuas nrog cov nplhaib ntawm geometry thiab thawj cov kev ntxhov siab. Rau cov ntawv ntsa tuab, cov nplej ntws tau zoo thoob plaws hauv tag nrho cov phab ntsa tuab, ua rau muaj kev npau taws, thiab ua kom tsis muaj zog, ua rau muaj kev sib zog ua ke nrog cov ciaj ciam nplej.

Dispersoids: nplua dispersids tsim los ntawm micro-alloying ntsiab (piv txwv li kev kho kom txaus siab, tsis muaj kev tswj hwm lub ntsej muag zoo, yog tsis muaj microstructure zoo.

Tsis tshua muaj zog thiab tsis muaj zog tshem tawm:

Qhov kev ntxhov siab rau lub sijhawm thaum lub sijhawm forging ua tiav txhua yam tsis xws luag, ua tiav cov kab ke sab hauv, ua kom ze rau sab hauv thiab cov kev txhim kho cov khoom siv hauv sab hauv.

Thawj qhov sib xyaw ua ke thiab cov kauj ruam uas neeg tawg xwm txheej yog ua rau muaj kev phom sij tsis zoo, txo qis lawv cov kev phom sij.

Cov kev faib tawm niaj hnub ntawm cov theem ntxiv ntawm theem (precipitates):

Txhim kho kev tswj ntawm kev kho cov ntsiab lus thiab kev ua kom muaj zog ntawm cov khoom siv tuab, yog li ua tiav cov kev sib txawv ntawm cov khoom siv tuab ntawm tag nrho cov kev sib txawv.

Cov hmoov nplej ib Zaug Morphology thiab faib cov pob khoom siv, tshwj xeeb yog cov qoob loo T73 \/ tshwj xeeb yog tsim, ua kom tiav rau kev ntxhov siab corrosion thiab exfoliation corrosion.

Metallurgical Huv:

Aerospace-qib melting thiab casting thev naus laus zis ua kom muaj cov ntsiab lus zoo nkauj tsawg, uas yog qhov tseem ceeb rau kev txhim kho pob txha mos thiab qaug zog lub neej.

4. Sab Nraud Cov Lus Qhia & Kev Ua Phem

Txoj kab uas loj loj-walled txhuas tau muab cov nplhaib loj heev hauv qhov loj me, uas xav tau tshwj xeeb ultra-khoom siv rau kev tsim khoom thiab tshuaj xyuas.

|

Chaw ua uas tsis tau haus |

Raug kev tsim khoom |

Kev Lag Luam Ua Lag Luam (AS-FIDED) |

Precision Kev Zam Txim (Machined) |

Txoj kev xeem |

|

Txheej hauv lub taub |

1000 hli - 8000+ hli |

{0. 5% lossis ± 10 hli (saib qhov twg yog dua) |

{{{{0}}}. 1 hli rau ± 0.8 hli |

CMM \/ Laser Scan |

|

Sab hauv Inch |

800 hli - 7900+ hli |

{0. 5% lossis ± 10 hli (saib qhov twg yog dua) |

{{{{0}}}. 1 hli rau ± 0.8 hli |

CMM \/ Laser Scan |

|

Phab Ntsa Thickness |

100 hli - 1200+ hli |

3% lossis ± 10 hli (saib qhov twg yog dua) |

{{{0}}}. 2 hli rau ± 1.0 hli |

CMM \/ Laser Scan |

|

Qhov siab |

100 hli - 1500+ hli |

3% lossis ± 10 hli (saib qhov twg yog dua) |

{{{0}}}. 2 hli rau ± 1.0 hli |

CMM \/ Laser Scan |

|

Huv |

N/A |

{{0 {}}. 5 hli \/ meter inch |

0. 1 hli \/ meter inch |

Flawe Gauge \/ CMM |

|

Kev Pom Zoo |

N/A |

0. 5 hli |

0. 1 hli |

Lub koob yees duab \/ cmm |

|

Nto roughness |

N/A |

Ra 12. 5 - 25 μm |

Ra 1. {6 - 6. 3 μm |

Profat |

Lub peev xwm custom:

Raws li cov khoom lag luam zoo heev, lawv tuaj yeem tsim thiab tsim tau tag nrho raws li cov neeg siv khoom siv cov ncauj lus kom ntxaws, suav nrog cov nplhaib sib dhos, thiab cov nplhaib sib xyaw nrog cov flanges lossis grooves.

Feem ntau muaj nyob rau hauv kev ntxhib machined lossis ib nrab ua kom yooj yim thiab precision rau cov qhua tuaj noj mov machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining machining tshuab

5. Kev Tsav Tsheb & Kev Kho Tshav Kub

Kev kho cua sov ntawm txoj kab hluav taws xob loj tuab-walled txhuas tau ntse rau kev ua tiav lawv cov kev ua tau zoo, nrog cov qauv nruj me ntsis rau cov qib sib txawv thiab cov ntawv thov yuav tsum tau ua.

|

Tauj Ntshav |

Kev piav qhia cov txheej txheem |

Muaj feem xyuam rau |

Cov yam ntxwv tseem ceeb |

|

O |

Tag nrho anealed, muag muag |

Tag nrho cov alloys aluminium |

Qhov siab tshaj plaws ductility, qis tshaj lub zog, yooj yim rau kev ua haujlwm txias |

|

H112 |

Tsuas yog pluav tom qab forging |

5xxx series |

Khaws cia forged microstructure thiab residual kev ntxhov siab, muaj zog nruab nrab, zoo corrosion tsis kam |

|

H321/H116 |

Ruaj khov tom qab forging |

5xxx series |

Kev nyuaj siab ntxhov siab heev corrosion thiab exfoliation tsis kam, siab dua lub zog dua H112 |

|

T6 |

Daws cov cua sov kho, ces muaj zog |

2xxx, 6xxx, 7xxx series |

Lub zog tshaj plaws, lub siab tawv, tab sis siab scc tau kev ua tau zoo hauv qhov chaw tuab |

|

T73/T74 |

Daws cov cua sov kho, tom qab ntawd siv ntau (ob-theem lossis ntau-theem) |

7xxx series (tshwj xeeb yog tuab-walled ntu) |

Tsawg me ntsis qis dua T6, tab sis kev nyuaj siab ntxhov siab corrosion thiab exfoliation tsis kam, siab pob txha tawv tawv |

|

T76 |

Daws cov cua sov kho, tom qab ntawd tshwj xeeb laus |

7xxx series |

Zoo tag nrho cov khoom, siab ntxhov siab corrosion tsis kam |

|

T79 |

Tshwj Xeeb Kev Kho Mob Cua Sov rau 7xxx alloys |

7xxx series (siab lub zog + siab SCC Kuj) |

Lub zog siab thiab tshwj xeeb kev ntxhov siab corrosion tsis kam (tshiab khiv) |

Cov Lus Taw Qhia Txog Kev Xaiv Tsa:

Rau cov ntaub falled forging dhuav, them nyiaj tshwj xeeb rau:

7xxx series: T73, T74, thiab T79 Tempers tau nyiam dua. Cov tempers no, los ntawm kev qhia kom meej, nce txhim kho kom ntxhov siab rau kev ntxhov siab (SCC) thiab nthuav tawm cov khoom siv nrawm nrawm hauv cov kab tuab. T6 Tauj yog ib qho feem ntau tsis pom zoo rau tuab-walled lossis sCC-rhiab daim ntawv thov.

5xxx series: H116 thiab H321 Tempers yog cov kev xaiv zoo tshaj plaws. Lawv muab cov kev ua siab loj ua rau muaj lub zog zoo thiab kev tawv tawv los ntawm kev kho mob tawv thiab muaj kev ruaj khov, tshwj xeeb yog tsim nyog rau cov tub rog thiab cryogenic ib puag ncig.

Residual ntxhov siab nyem: Rau tag nrho cov ntaub falled forgings, kev kho kom ncab (TXUPTING (0)

6. Machining & Fabrication Cov yam ntxwv

Machining loj txoj kab uas muaj lub zog sib tw yog cov cuab yeej nyuaj heev thiab cov tswv yim tsim kho kom raug rau lawv qhov loj thiab kev ntxhov siab.

|

Kev phais |

Lub cuab yeej |

Pom zoo parameter ntau |

Lus |

|

Txoj siav |

Carbide, pcd |

Siab txiav ceev vc =100-400 m \/ min, pub f =0. 8 hli \/ rev |

Loj lathes, high-fais ntxaiv, kev co zoo damping, muaj ntau txias |

|

Milling |

Carbide, hss |

Siab txiav ceev vc {=150-600 m \/ min, pub rau ib leeg hniav fz {}}. {2}}. 5 hli |

Loj gantry mills \/ 5- Axis Machine, qhov tob loj ntawm kev txiav, high pub, ua haujlwm nti tawm |

|

Kev drilling |

Carbide, dlc coated |

Nruab nrab txiav ceev vc =40-100 m \/ min, pub f =0. 2 hli \/ rev |

Los ntawm kev xyaum ua kom tiav, kev sib nqus tob, kev sib sib zog nqus lub voj yuav tsum muaj ntau cov pecking mus, zam nti clogging |

|

Vuam |

MIG \/ TIG \/ FSW |

Cov xaim xaim thiab thaiv cov roj xaiv raws li qib alloy |

5xxx \/ 6xxx Series yog weldable; 2xxx \/ 7xx Xight Muaj kev pab cuam tsis zoo ntawm weldability, xav fsw lossis tshuab koom nrog |

|

Txias ua haujlwm |

Saib Tauj |

Ductility zoo, tso cai rau cov txheej txheem tiv thaiv loj |

T \/ H Tempers muaj qis dua lub plab, muaj kev tiv thaiv loj dua |

Kev Ncaj Ncees:

Muaj Zog Thiab Cov Cuab Yeej Rigidity High: Kev muag khoom tau txhaj tshuaj loj

Kev tswj hwm kev ntxhov siab: Vim yog cov high quenching residual kev nyuaj siab nyob rau hauv tuab-walled forging forging, thiab feem ntau cov kev kho mob kub, thiab muaj feem cuam tshuam nrog tshav kub kub

Tooling thiab cua txias: Siv cov ntse thiab hnav-resistant carbide lossis cov cuab yeej PCD, ua ke nrog kev tawm tsam zoo, txo cov chaw txiav tawm qhov kub, thiab txuas ntxiv ua lub neej.

Machining distortion tswj: Kho kom haum rau Machining kev npaj ua haujlwm, kev txiav kev tsim nyog txiav, thiab siv clamping zoo rau kev tswj tshuab distortion.

Nto Zoo: High precision thiab tsawg reagns chaw tuaj yeem ua tiav los ntawm kev ua tiav, txo qhov kev xav tau ntawm kev sib tsoo thiab polishing.

7. Corrosion Kuj & Kev Tiv Thaiv Cov Tshuab

Daim ntawv thov ntawm loj txoj kab uas muaj cov nplhaib xav tau rau hauv lawv cov kev coj ua kom zoo, tshwj xeeb tshaj yog hais txog kev coj tus cwj pwm hauv cov kab tuab.

|

Corrosion hom |

Raug |

Corrosion Hom kev txhawj xeeb & kev tiv thaiv |

|

Atmospheric corrosion |

Zoo |

Nto Kho, Huv Txij Nkawm |

|

Dej hiav txwv corrosion |

5xxx series zoo heev, lwm cov koob muaj kev tiv thaiv |

Anodizing, Kev Ua Haujlwm Siab Zoo, Kev Tiv Thaiv Cathodic, Galvanic Kev rho tawm |

|

Kev ntxhov siab corrosion cracking (SCC) |

2xxx \/ 7xxx T6 rhiab, T73 \/ T74 \/ T79 zoo heev |

Alloy \/ Twj Xaiv (T7x), kev nyuaj siab nyem, kev kho saum npoo |

|

Exfoliation corrosion |

2xxx \/ 7xxx T6 rhiab, T73 \/ T74 \/ T79 zoo heev |

Alloy \/ Tement xaiv (T7X), Grain Flow Control, Kev Kho Mob |

|

Intergranular corrosion |

Tej zaum yuav tshwm sim nrog kev kho kom sov sov los yog rhiab |

Kev Kho Cua Sov, Kev Tswj Xyuas Kev Sib Tw |

|

Pitting corrosion |

Tej zaum yuav tshwm sim hauv chloride-muaj cov xov xwm |

Nto Kho, Huv Txij Nkawm |

Kev Tiv Thaiv Cov Tshuab:

Alloy thiab npau taws xaiv: Xaiv cov qhab nia sib txawv thiab kho cua sov kho kom zoo rau cov chaw tsim khoom, xws li 7xxx Series ntawm cov khoom siab muaj siab nrog lub siab SCC \/ exfoliation tsis kam.

Nto Kho:

Txoj kev: Rau txoj kab uas loj loj-rings, ntaus II (sulfuric ib txwm siv, muab cov tuab neeg III (nyuaj-tiv taus oxide zaj duab xis.

Kev Siv Tshuaj Conversion Coneings: Ua raws li cov cim npe zoo rau cov xim lossis cov nplaum, muab cov kev tiv thaiv corrosion yooj yim thiab cov nplaum.

Kev Ua Haujlwm Zoo Tshaj \/ Txheej Txheej: Multi-Txheej Epoxy Primer + Polyurethane Topcoat Topcoat yog siv rau cov tub rog loj tshaj plaws, thiab ib puag ncig tub rog, thiab chaw ua tub rog. Tshwj xeeb cov txheej txheem tshwj xeeb (piv txwv li, tej hub hnav khaub ncaws) yuav siv rau cov haujlwm tshwj xeeb.

Tsim thiab Kev Tsim Kho: Zam kev ntxiab dej, crevices, thiab galvanic corrosion tshwm sim los ntawm kev sib cuag nrog cov sib luag; Thov kev tiv thaiv insulating lossis kev tiv thaiv Cathodic thaum tsim nyog.

8. Lub zog rau cov engineering tsim

Lub zog lub cev ntawm txoj kab uas loj loj-ntsa aluminium forged cov nplhaib yog qhov tseem ceeb rau cov qauv ntawm cov qauv loj.

|

Ntiag tug |

Cov nqi raug |

Tsim Kev Txiav Txim Siab |

|

Ceev |

2. {{66 - 2. 85 g \/ cm³ |

Kev tsim lub tsho loj heev, kev ua kom zoo ntawm nruab nrab ntawm cov kev sib tsoo thiab cov khoom tsim |

|

Melting ntau |

500 - 650 degree |

Kev Kho Cua Sov thiab Kev Siv Vuam Tshwj Xeeb (piv txwv li FSW) Kev tswj lub ntsuas |

|

Thermal conductivity |

110 - 200 W/m·K |

Kev tswj hwm cua sov, daim ntawv thov hauv cov khoom siv kub dissipation lossis rwb thaiv tsev. |

|

Hluav Taws Xob Kev Tshaj Tawm |

30 - 55% IACs |

Hluav taws xob cuam tshuam lossis tiv thaiv kev tiv thaiv cov khoom siv hluav taws xob |

|

Cov cua sov tshwj xeeb |

860 - 900 J \/ Kg · K |

Thermal inertia, thermal poob siab teb muab xam |

|

Thermal Expansion (CTE) |

22 - 24 ×10⁻⁶/K |

Kub-inductsalsal hloov nyob rau hauv cov khoom siv loj, cov khoom siv xaiv kev sib koom tes |

|

Cov tub ntxhais hluas lub modulus |

70 - 75 GPA |

Cov qauv tawv tawv, deformation, thiab kev ntsuas co |

|

Poisson tus piv |

0.33 |

Cov Txheej Txheem Ntsuam Xyuas Parameter |

|

Damping muaj peev xwm |

Nruab nrab-qis |

Kev co thiab suab nrov tswj, xav tau kev sib xyaw nrog cov qauv tsim qauv |

Kev txiav txim siab tsim:

Kev ua kom loj hlob heev thiab cov txheej txheem kev ua tau zoo: Leveraging qhov ntom ntom nti ntawm aluminium alloys thiab lub zog siab ntawm kev zam txim kom ua tiav qhov kev ua haujlwm hnyav, uas yog qhov ceev ceev, thiab tsheb ciav hlau.

Thauj khoom hloov thiab kev nyuaj siab concentration: Cov nplej optimized cov xaim ntws thiab ntom micrittructure muab los ntawm Forging kev hloov chaw, txo kev ntxhov siab kev ntxhov siab, thiab txhim kho lub neej qaug zog.

Kev Zam Txim Rau Tsim: High Pob Txha Kev Sib Tw Tso Cai Ua Cheebtsam kom tiv thaiv kev tsim qauv txawm tias muaj qhov tsis xws luag me me, nce cov txheej txheem kev nyab xeeb kev nyab xeeb.

Txoj Kev Ib Cheeb Tsam Adjust: Xaiv cov alloy uas tsim nyog tshaj plaws thiab kev kho cua sov kom haum rau qee yam xws li kev ua kom xeb, ntau yam kev co, thiab kev cuam tshuam cov ntsaws.

Machining thiab sib dhos sib cuam tshuam: Yuav tsum tau tsim kho kom zoo thiab nruj kev tiv thaiv kev tswj hwm kom ntseeg tau tias cov khoom zoo tshaj plaws nrog cov cheebtsam uas nyob ib sab.

9. Kev Tsim Kho Zoo & Kev Xeem

Kev lees paub zoo thiab kuaj cov kab uas loj loj heev ua ntej kev kuaj cov khoom tseem ceeb ua ntej kev sim ua tsis yog kev sim ua tsis yog kev ua phem rau sab hauv.

Cov Qauv Kuaj Cov Txheej Txheem:

Cov Khoom Siv Raw Tag Nrho Lifeausility: Los ntawm Inpot rau cov khoom kawg, txhua zaus ntau lawm, ua cov txheej txheem, thiab cov txiaj ntsig kev sim ua tiav.

Tshuaj Muaj Kev Ntsuam Xyuas Kev Ntsuam Xyuas: Siv Optical emission tsom, X-Voj Fluorescence ua raws cov qauv thiab cov neeg tawg siab tsim nyog tau tswj hwm rau cov qauv tsis tseem ceeb (piv txwv li, ZN, Cu, ZR).

Yaj thiab ingot zoo tswj: Cov kev ntsuas tshuab hluav taws xob hydrogen tshem tawm, los ntawm cov hau kev zoo li Sep 1920\/1940 lossis DDA-P940 lossis ingot macrologegation soj ntsuam, grain loj kev tshuaj ntsuam xyuas.

Forging Txheej Txheem Xyuas: Real-sij hawm kaw thiab saib xyuas kev quav ntsej muag kub, qhov siab, tus nqi deformation, thiab deformation tus nqi los ua kom pom tseeb.

Kev Kho Cua Sov Kev Tshuaj Ntsuam: Cov cua sov ua ke kub (feem ntau sib ntsib Ams 2750 chav kawm 1 lossis 2), tshem tawm cov kev nkhaus, thiab lwm yam.

Kev tshuaj xyuas seem thiab cov ntsuas hluavtaws: Kev tshuaj xyuas sab nraud ntawm sab nraud thiab sab hauv, cov duab tuab, thiab txhua lwm qhov tseem ceeb, thiab tag nrho lwm qhov tseem ceeb, thiab tag nrho lwm qhov tseem ceeb, thiab tag nrho lwm qhov tseem ceeb, thiab tag nrho lwm qhov chaw ntsuas, thiab txhua yam qhov siab, thiab cov tshuab ua kom zoo nkauj (cms) lossis laser scanning tshuab.

Cov Cuab Yeej Cuab Yeej Cuab Yeej Cuab Yeej:

Samling: Rau cov tuab-falled zam txim, qhov chaw coj mus kuaj thiab ntau yog qhov tseem ceeb. Cov qauv feem ntau yuav tsum tau coj los ntawm sab hauv, nruab nrab, thiab kev ntsuas sib txawv ntawm cov nplhaib sib dhos

Kev kuaj: Qhov kawg tensile lub zog, tawm los lub zog, kev txo qis, nkees ua lub zog kev loj hlob (da \/ dn), pob txha lov (K1c).

Kev Tshaj Tawm Tshwj Xeeb: Stress Corrosion Cracking (SCC) tests (eg, C-ring, SSRT, loaded beam tests, especially for 7xxx series T73\/T74\/T79), Exfoliation Corrosion (EXCO, ASTM G34).

Nondestructive Testing (NDT):

Ultrasonic kuaj: 100% puv-ntim, ntau-kaum sab xis, siab-sensitivity ultrasonic tshuaj xyuas ntawm tag nrho lub nplhaib. Rau cov tuab uas tuab, qhov no yog qhov tseem ceeb tshaj plaws rau kev kuaj pom kev tsis taus sab hauv, xav tau kev ua raws li cov qauv hauv nroog

Kev Kuaj Penetrant: Ntes nto tawg tsis xws luag rau txhua qhov chaw tshuab.

Eddy kev sim tam sim no: Tshawb xyuas cov npoo thiab ze--nthab tsis xws luag, xws li micro-tawg thiab hardness tsis-uniformity.

Xov Tooj Cua|(yeem): Rau kev tshuaj xyuas kev soj ntsuam ntawm sab hauv tej yam tsis xws luag lossis cov ntaub ntawv pov thawj ntxiv.

Kev Ntsuam Xyuas Microstruction: Daim ntawv qhia tshuaj ntsuam xyuas kom ntsuas cov qoob loo loj, cov khoom siv thiab faib tawm, tsis txaus ntseeg, kom meej raws li cov qauv hlau me me.

Nto roughness ntsuas.

Cov Qauv thiab Ntawv Pov Thawj:

Cov qauv kev nruj tshaj plaws thoob ntiaj teb thiab kev lag luam kev lag luam, xws li Ams (Aerospace Cov Khoom Siv Tshwj Xeeb), ISO, EN, GB \/ T, ETC.

Kev tswj hwm kev tswj hwm cov txheej txheem zoo: ISO 9001, AS9100 (AER9100 (AER9100 (Nadcap (cov txheej txheem tshwj xeeb, xws li kev kho cua sov, NDT).

Muaj cov ntawv qhia txog kev kawm, thiab cov ntawv pov thawj thib peb uas peb sab nraud tuaj yeem raug npaj raws li cov neeg siv khoom thov.

10. Kev Siv & Tsim Tsim

Txoj kab uas loj loj-duav txhuas yog cov khoom siv uas nyiam tshaj plaws nyob rau hauv cov kev thov tseem ceeb thiab kev tsis muaj peev xwm ua tau zoo thiab ntseeg tau.

Cheeb Tsam Thov:

Ib tug tub rog:

Lub dav hlau Cav Xwm: Xws li cov kiv cua ntse, cov rooj sib txuas, cov kab mob ib txwm muaj, cov kabmob kub, thiab nrawm nrawm nrawm nrawm, thiab kev kub siab.

Loj tsaws iav txheej txheem teeb tsa: Raug rau kev cuam tshuam loj heev thiab qaug zog.

Rocket thiab Missile Cov Qauv: Interstage kev sib txuas cov nplhaib, lub tshuab thrust thav ntawv, cov nplhaib sib tw, xav tau lub zog kawg thiab lub teeb yuag.

Chaw Chaw Nres Tsheb thiab Satellite tseem ceeb: Cov ris-coj cov nplhaib sib tw, rocking tshuab rings.

Zog Kev Lag Luam:

Nuclear fais fab cog cov tseem ceeb: Muaj cov twj txuas ntxiv, siab txog lub nkoj loj flanges, xav tau kev ntseeg siab heev thiab corrosion tsis kam.

Cua Turbine Main Ncej Flanges Thiab Ntauwd Txuas Rings: Raug rau cov cua ntsawj ntshab thiab qaug zog.

Lub nkoj loj loj thiab cov khoom siv tank cia: Rau tshuaj, petrochemical, lng (liquefied muaj txiaj ntsig zoo thiab kev thauj khoom muaj txiaj ntsig zoo thiab cryogenic nyuaj.

Ultra-siab siab Hydrogen Rauv Tank Rings: Tsis tshua muaj neeg xav tau rau hydrogen embrittlement thiab qaug zog lub neej.

Marine engineering:

Deep-Hiav Txwv Sharmersible Siab Hull Txuas Cov Rings: Raug rau cov dej siab tsis zoo.

Kev txhawb nqa tseem ceeb rau kev siv hluav taws xob tua hluav taws: Xav tau cov dej hiav txwv zoo heev thiab thauj khoom muaj peev xwm coj tus kheej.

Loj nkoj lub rooj zaum: Xws li cov dav hlau thauj khoom raug ntes iav cov qauv, cov tsheb thauj khoom uas muaj tsheb thauj khoom tsaws iav.

Tub rog teb:

Cov Art Strike thiab Turret Sib Tw: Muaj cov khoom tseem ceeb recoil thiab cuam tshuam.

Cov khoom lag luam tseem ceeb ntawm cov kabmob sib tw rau cov tsheb hnyav.

Missile pib raj Rings.

High-Xaus Cov Machinery:

Cov kabmob loj kabmob: Xws li rau lub qhov tho txawv tshuab lub ntsiab bearings.

Loj iav Xauj, Nplhaib Taub Hau.

Tsim Zoo:

Qhov kawg lub zog-rau-luj piv: Lub rooj sib tham lossis txawm tias Steel lub zog yuav tsum tau txo qis thaum ua tiav qhov hnyav tsis zoo, uas yog qhov tseem ceeb rau kev txhim kho kev thauj khoom thauj zoo thiab txo kev siv hluav taws xob.

Kev tsis muaj kev cia siab tsis muaj kev cia siab thiab kev nyab xeeb: Cov txheej txheem Forging ua tiav tshem tawm cov kev tshem tawm, ua ke nrog kev nyab xeeb nruj thiab ua kom muaj kev nyab xeeb rau cov khoom siv hnyav tshaj plaws thiab ib puag ncig.

Cov kev tiv thaiv zoo heev: High fracture toughness and resistance to fatigue crack propagation allow components to operate safely for a period even with minor defects, providing valuable safety margins.

Zoo ib puag ncig kev hloov tau: Tshwj xeeb cov alloy optimized rau cryogenic (piv txwv li, lng) thiab corrosive (piv txwv li) ib puag ncig) ib puag ncig) kev ua yeeb yam tsis sib xws los ntawm cov hlau.

Seem ruaj khov: Los ntawm cov seem kev ntxhov siab, ua kom cov siab muaj qhov tseeb ntawm cov hlua loj thaum lub sijhawm ua haujlwm ncaj ncees.

Cov Qauv Txwv & Kev Sib Tw:

Tsis tshua muaj nqi: Yuav tsum tau cov khoom siv tsis zoo, kev tswj cov txheej txheem nyuaj, thiab cov qauv kev soj ntsuam zoo dua li lwm cov ntaub ntawv thiab kev tsim khoom.

Ntev mus ua voj voog: Complex Forging thiab cov txheej txheem kho cua sov, thiab cov txheej txheem tshuaj ntsuam xyuas kom ntev ua rau ncua kev tsim khoom.

Machining nyuaj: High-zog zog alloys muaj kev sib tw siab thiab muaj feem xyuam rau cov kev txhawj xeeb ntawm tshuab, thiab cov tswv yim zoo.

Hwj txwv: Feem ntau ultra-siab-zog aluminium alloys (tshwj xeeb yog 7xxx series) muaj kev sib haum xeeb weldability, txwv txoj kev koom nrog; Mechanical koom nrog lossis lub luag haujlwm-lub xeev koom nrog (piv txwv li FSW) feem ntau yuav tsum tau ua.

Kev ua ntsuas kub siab: Aluminium alloys feem ntau tsis txhob ua kom muaj qhov kub thiab txias; Ntev ntev ua haujlwm kub yog txwv rau hauv qab 120-150 degree, saum toj no cov khoom yuav cuam tshuam ntau.

Kev Lag Luam thiab Kev Txiav Txim Siab:

Tag nrho lub neej lub neej: Txawm tias muaj kev pheej yig, lawv txoj kev ua haujlwm siab ntev, thiab poob phaus ntev dhau cov khoom lag luam tseem ceeb tshaj qhov khoom txheej txheem lub neej.

Cov peev txheej: Forging, raws li ib tug nyob ze-net cov qauv txheej txheem, ua tau zoo txo cov khoom siv raw; Aluminium lub siab rov ua dua tshiab kuj tau ua kom haum nrog kev lag luam kev lag luam ncig.

Cov txiaj ntsig ib puag ncig: Lub teeb yuag yuag, ua rau kom txo qis zog thiab carbon emissions, muaj kev tiv thaiv ib puag ncig.

Cim npe nrov: Thooj Thiaj Thooj Loj Walled Aluminium Forged nplhaib, Tuam Tshoj Loj Inced Ring Manufacturers, lwm tus neeg, Hoobkas

Xa kev nug