6061 Txoj Kab Loj Loj Loj Alloy Bar

6061 Cov kab ntsig loj-txheej txhuas alloy rods ua kev tiv thaiv tseem ceeb, kev tiv thaiv zoo, zoo li cov ntawv thov muaj ntau yam.

1.}} cov khoom siv & cov txheej txheem tsim khoom

6061 Txoj kab ke loj loj heev Alloy Bar yog qhov ntau ntawm cov txheej txheem, thiab cov tshuab hluav taws xob zoo tshaj plaws, kev thauj mus los, thiab kev lag luam engineering:

Tseem Ceeb Alloying Ntsiab:

Magnesium (MG): 0.8-1.2% (txhim kho lub zog)

Silicon (si): {{0.4-0.8% (cov ntawv mg₂si ntxiv dag zog rau theem nrog magnesium)

Tooj Liab (Cu): 0.15-0.40% (txhim kho lub zog, txo cov corrosion tsis kam)

Chromium (CR): {0.04-0.35% (inhibits recrystallization, txhim kho kev ntxhov siab corrosion)

Cov khoom siv hauv paus:

Aluminium (Al): Ntau dua lossis sib npaug rau 95.8% (tshuav nyiaj li cas)

Kev tswj kev impurities:

Hlau (FE): tsawg dua lossis sib npaug rau 0.70% Max

Zinc (Zn): Tsawg dua lossis sib npaug rau 0.25% Max

Manganese (MN): Tsawg dua lossis sib npaug rau 0.15% Max

Titanium (ti): tsawg dua lossis sib npaug nrog 0.15% Max

Lwm cov ntsiab lus: Tsawg dua lossis sib npaug rau 0.05% txhua, tsawg dua lossis sib npaug ntawm 0.15% tag nrho

Cov Txheej Txheem Tsim Tau:

Kev npaj yaj:

High-purity thawj txhuas (99.7% yam tsawg kawg nkaus)

Ua kom meej alloying ib qho ntxiv nrog ± 0.05% kam

Kev ua kom tau lim dej ua npuas ncauj (30-40 ppi)

Snif Degassing Kev Kho (Hydrogen <0.10 ml / 100g)

Lis cov kws ua kom zoo nrog al-ti-b tus tswv alloy

Qhov ncaj-ntawj txias (DC) txuas ntxiv ua ntu zus los ua cov kab uas hla loj loj

Homogenization:

{{0 {}}℃rau 6-12 teev

Uniform kub tswj: ± 5 degree

Kev tswj kom txias tus nqi: 15-25℃/ teev

Kev tshem tawm ntawm coarse intermetallics, tshem tawm ntawm microRubration

Kub ua haujlwm (Extrusion lossis Forging):

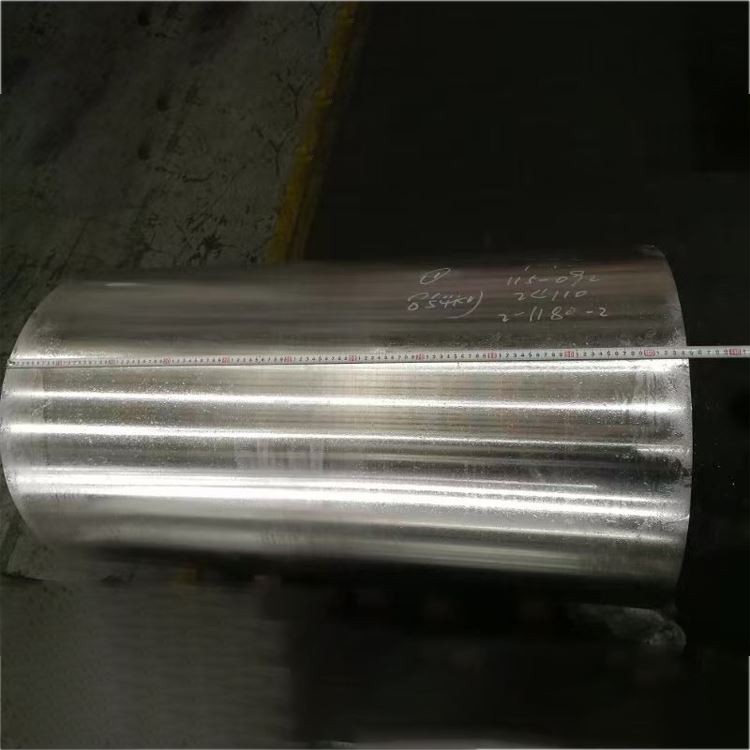

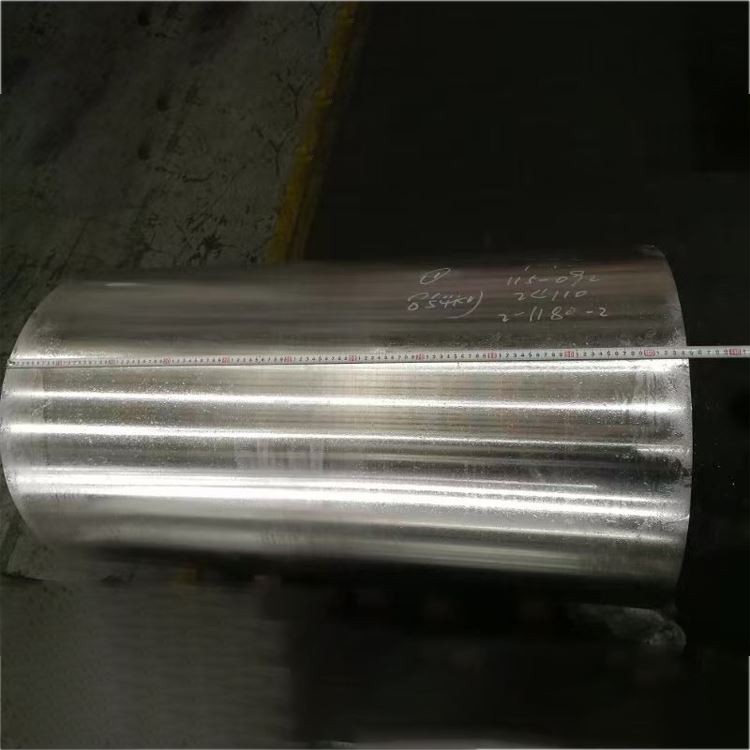

Loj Extrusion Presses: Muaj peev xwm ntawm kev tsim cov khoom sib xws li 400Mm lub taub

Los yog forging: Ua kev cuam tshuam rau hauv cov kab ntawm radial forging lossis kaw-tuag forging

Deformation kub: 450-500 degree

Paub tseeb tias muaj kev deatormation txaus thiab cov nplej ua kom zoo rau kev pom zoo sab hauv thiab grain

Tshuab Kev Kho Mob Kub:

{{0520-550℃rau 1-4}} teev (taub nyob)

Cov ris tsho kub: ± 3 degree

Hloov pauv sai sai (<10 seconds)

Quenching:

Dej queny lossis polymer quench

Kev tswj cov nqi txias rau kev ua kom nyuaj

Kev ntxhov siab nyem (rau T651 / T6511 Tempers):

Tswj ncab ({1-3}}% excormation) kom txo qis kev ntxhov siab

Kev laus cuav (T6 npau taws):

{{0 {}}℃rau 8-18 teev

Cov ris tsho kub: ± 3 degree

Txhua qib ntau lawm yog raug rau kev tswj hwm nruj heev thiab traceability tswj .

2.} cov khoom siv mechanical ntawm 6061 txoj kab uas hla loj Aluminium Aluminium

|

Ntiag tug |

O (anealed) |

T4 |

T6 |

T651/T6511 |

Txoj kev xeem |

|

Qhov kawg tensile lub zog |

110-145 mpa |

180-220 mpa |

290-320 mpa |

290-320 mpa |

ASTM E8 |

|

Tos lub zog (0.2%) |

40-60 mpa |

90-120 mpa |

240-270 mpa |

240-270 mpa |

ASTM E8 |

|

Elongation (2 nti) |

16-25% |

14-20% |

8-15% |

8-15% |

ASTM E8 |

|

Hardness (Brinell) |

30-40 hb |

60-75 hb |

95-105 hb |

95-105 hb |

Astm E10 |

|

Qaus zog zog (5 × 10⁸ mus) |

70-90 mpa |

90-110 mpa |

95-110 mpa |

95-110 mpa |

ASTM E466 |

|

Tawv muaj zog |

70-90 mpa |

110-130 mpa |

190-210 mpa |

190-210 mpa |

ASTM B769 |

|

Modulus ntawm elasticity |

68.9 GPA |

68.9 GPA |

68.9 GPA |

68.9 GPA |

Astm E111 |

Vajtsoob:

Axial vs . radial cov khoom:<5% variation in strength properties

Cov cuab yeej sab hauv variation hla txoj kab uas hla loj: feem ntau tsawg dua 7% rau T6 / T651 Tempers

Cov tub ntxhais mus rau saum npoo hardness variation:<5 HB

Residual kev ntxhov siab: qib kev ntxhov siab qis hauv T651 / T6511 Tempers, txo Machining distortion

3.} microstructural yam ntxwv

Qhov Tseem Ceeb Microstructural nta:

Grain qauv:

Elongated nplej nrog qee cov recrystallized nplej tom qab kub ua haujlwm

ASTM grain loj 4-7 (90-32 μm)

Txhim kho cov qauv grain thiab ua kom zoo nyob hauv txoj kab uas loj loj ntawm cov txheej txheem tswj nruj

Precipition faib:

Mg₂si ntxiv dag zog rau theem: nplua nuj thiab uniformly dispersed, muab kev txhawb zog tseem ceeb

Alfesi Intermetallics: tswj qhov loj me thiab faib

Cr₂si lossis Al₁₂mg₂cr Dispersids: inhibits Grand Kev Loj Hlob, txhim kho kev ntxhov siab corrosion tsis kam

Kev Kawm Ntawv:

Cov Kev Ntsuas Cov Fiber Qhia Tawm los ntawm Extrusion / Forging

Lub zog muaj zog tau cuam tshuam me rau ntawm cov khoom siv tshuab; Cov tshuab ua kom zoo nkauj thiab nag lossis daus ua tawv tawv yog qhov tseem ceeb

Cov Nta Tshwj Xeeb:

Cov khoom sib faib ntawm precipitates ntawm cov ciaj ciam av

Superersaturated cov kev daws teeb meem tom qab daws teeb meem

Tsim ntawm cov theem nag lossis daus tom qab kev kho mob

4.} Qhov ntev tshaj tawm & kev thev taus

|

Chaw ua uas tsis tau haus |

Cov Qauv Qeb |

Precision Kev Zam |

Kev Lag Luam Ua Lag Luam |

Txoj kev xeem |

|

Qhov dav |

100-600 hli |

± 0.5 hli txog 200 hli |

± 1.0mm txog 200 hli |

Micrometer / Caliper |

|

± 0.25% saum 200 hli |

± 0.5% tshaj 200 hli |

|||

|

Kev tuag tuag tuag tuag |

N/A |

50% ntawm txoj taub no tsis kam |

75% ntawm txoj kab uas hla |

Micrometer / Caliper |

|

Qho ntev |

1000-7000 hli |

± 5mm |

± 10mm |

Daim kab xev ntsuas |

|

Ncaj |

N/A |

0.8 hli / m |

1.5 hli / m |

Ncaj / Laser |

|

Nto roughness |

N/A |

3.2 μm RA Max |

6.3 μm RA Max |

Profat |

|

Txiav qhov sib luag |

N/A |

0.5 Degree Max |

1.0 teev max |

Tus muaj zog |

Qauv muaj cov qauv:

Txoj kab loj loj puag ncig: diameters 100mm rau 600 hli

Kev cai txiav-rau-ntev kev pabcuam muaj

Kev tsim kom muaj txiaj ntsig tshwj xeeb thiab cov nplaim dej ua tiav (e {{{} g}}}}}, peeled, precision muab) muaj thaum thov

Muaj nyob rau hauv as-quenched thiab laus, lossis quenched-ncab-hnub nyoog (T651) Tempers

5.}}}}} Kev Kho Mob Cua Sov

|

Tauj Ntshav |

Kev piav qhia cov txheej txheem |

Qhov Zoo Tshaj Ntawv |

Cov yam ntxwv tseem ceeb |

|

O |

Tag nrho anealed, muag muag |

Cov ntawv thov yuav tsum tau siv ntau qhov muaj peev xwm |

Qis tshaj plaws lub zog, siab tshaj plaws ductility |

|

T4 |

Daws cov tshuaj kub kho thiab muaj hnub nyoog zoo |

Muaj kev tsim muaj zoo nrog cov kev yuav tsum muaj zog |

Lub zog nruab nrab, muaj kev muaj zog |

|

T6 |

Daws cov tshuaj tiv thaiv tshav kub thiab muaj zog |

High-zog, cov ntawv thov txheej txheem |

Siab tshaj plaws lub zog thiab hardness |

|

T651 |

T 6 + kev nyuaj siab relieved los ntawm ncab |

Cov txheej txheem tseem ceeb, tsis muaj kev ntxhov siab tsawg |

Zoo kawg nkaus tas ruaj khov, qis machining distortion |

|

T6511 |

T 6 + me ntsis ncab + ncaj |

Tsawg residual kev ntxhov siab rau cov duab tsis xwm yeem |

Zoo ib yam li T651, tab sis rau cov neeg hla kev hla |

Cov Lus Taw Qhia Txog Kev Xaiv Tsa:

O: Rau cov haujlwm txias ua haujlwm

T4: Rau cov ntawv thov uas yuav tsum tau tsim los yog vuam, nrog kev kho cua sov kawg

T6: rau cov qauv dav dav thiab cov tshuab yuav tsum muaj zog

T651 / T6511: Rau txoj kab uas hla loj me uas yuav tsum muaj tsawg dua Machining Distortion thiab High Dimensional Stability

6. tshuab machining & Fabrication tej yam

|

Kev phais |

Lub cuab yeej |

Pom zoo tsis |

Lus |

|

Txoj siav |

Carbide, Pob Zeb Diamond |

VC =250-600 m / min, f =0.1-0.5 hli / rev |

High-ceev machining machining zoo heev nto ua tiav |

|

Kev drilling |

Carbide, Tin coated |

VC =80-200 m / min, f =0.15-0.40 hli / rev |

Los ntawm kev ua kom tiav txoj kev ua kom tau zoo, zoo rau qhov tob qhov |

|

Milling |

Carbide, hss |

VC {=200-800 m / min, fz =0.1-0.25 hli |

High-ins lub kaus sab lub kaum sab xis, loj tob ntawm kev txiav, siab noj |

|

Tab tom |

Hss-e-pm, ticn coated |

Vc =20-40 m / min |

Txoj xov zoo zoo, yooj yim rau Kais |

|

Tus rov ua dua |

Carbide, hss |

VC =80-150 m / min, f =0.2-0.6 hli / rev |

H7 / H8 zam kev ua tiav |

|

Sawing |

Carbide-Tipped Hniav |

Vc =1000-3000 m / min |

Kev txiav kev txiav, du txiav |

Kev Taw Qhia Fabricance:

Luam Ntawv Ntsuas: 80% (1100 Al ... 2}}}}}%), txhim kho tshuab chim

Nti Tsim: Yooj yim cov ntaub ntawv luv luv, chips curled, kev sib tw tso tawm chip

Coolant: Dej-Soluble Txiav Kua (5-10}}% concentration)

Tuam Kev Hnav: Qes, Ua Rau Ntev Tool Lub Neej

Weldability: Zoo heev nrog Tig thiab Mig vuam, tsawg zog poob tom qab vuam

Kev kho cua sov: tuaj yeem quenched thiab laus los txhim kho lub zog

Anodizing: yooj yim anodized rau kev ua kom zoo nkauj thiab corrosion-resistant qhov chaw

Brazing thiab soldering: tau

Residual kev nyuaj siab: T651 Cov Tempers Tempers tau txo qis kev ntxhov siab, txo cov machining tshuab distortion

{{07. corrosion Kuj & Kev Tiv Thaiv Cov Tshuab

|

Ib puag ncig hom |

Kev Ntsuas |

Kev Tiv Thaiv Txoj Kev |

Kev cia siab |

|

Muaj cua |

Zoo heev |

Huv si saum npoo, xaiv Anodizing |

15-20+ xyoo |

|

Marine cua |

Zoo |

Anodizing + sealing lossis pleev xim |

5-10+} xyoo nrog kev saib xyuas |

|

Dej hiav txwv immersion |

Ncaj |

Cathodic tiv thaiv lossis tha xim |

Nyob ntawm cov txheej zoo |

|

Siab vaum |

Zoo heev |

Huv si saum npoo, xaiv Anodizing |

10-15+ xyoo |

|

Kev ntxhov siab corrosion |

Zoo heev |

Kev ua tau zoo tshaj plaws hauv T6 npau taws |

Tsawg kev ua tau zoo |

|

Kho |

Zoo heev |

Kev tiv thaiv tus qauv |

Kev ua tau zoo tsis kam |

|

Galvanic corrosion |

Zoo |

Kom muaj kev sib cais |

Ceev faj tsim nrog cov sib luag |

Kev Xaiv deg Nto:

Anodizing:

Hom II (Sulfuric): {10-25 μm thickness, rau kev tiv thaiv zoo nkauj thiab kev tiv thaiv zoo

Hom III (nyuaj): {{{{}} μm thickness, rau hnav tsis kam thiab siab tiv thaiv

Dyeing thiab sealing: txhim kho kom zoo nkauj thiab corrosion tsis kam

Kev hloov dua tshiab txheej:

Cov chromate hloov dua lub koob txheej txheem (mil-dtl -5541}): kev tiv thaiv zoo heev thiab kev tiv thaiv corrosion

Kev Xaiv Cov Chromium-Dawb: Ib puag ncig raws li

Lub tshuab tha xim:

Epoxy Primer + Polyurethane Topcoat: rau qhov chaw hnyav

Hmoov Txheej: Muaj Siab Durability thiab Aesthetics

Lwm tus:

Electroplating, lub tshuab nqus tsev, thiab lwm yam .

{{08. Cov Khoom Siv Rau Lub Cev Rau Cov Kws Tsim Khoom Lag Luam

|

Ntiag tug |

Tus nqi |

Tsim Kev Txiav Txim Siab |

|

Ceev |

2.70 g / cm³ |

Kev ntsuas hnyav thiab cov qauv kev ua kom zoo |

|

Melting ntau |

582-652 degree |

Kev Kho Cua Sov Thiab Vuam Qhov Rooj |

|

Thermal conductivity |

167 W/m·K |

Thaum tshav kub dissipation thiab hloov tsim |

|

Hluav Taws Xob Kev Tshaj Tawm |

40-43% IACs |

Hluav Taws Xob Kev Siv Hluav Taws Xob |

|

Cov cua sov tshwj xeeb |

897 J / Kerg · K |

Thermal Mass thiab cua kub muaj peev xwm |

|

Thermal Expansion (CTE) |

23.6 ×10⁻⁶/K |

Kev hloov sab nraud vim yog qhov kub hloov pauv |

|

Cov tub ntxhais hluas lub modulus |

68.9 GPA |

Deflection thiab stiffness suav |

|

Poisson tus piv |

0.33 |

Cov Txheej Txheem Ntsuam Xyuas Parameter |

|

Damping muaj peev xwm |

Nruab nrab-qis |

Kev co thiab suab nrov tswj |

Kev txiav txim siab tsim:

Kev Ua Haujlwm Kub Ntau Yam: {-80℃rau +150 degree

Kev ua yeeb yam kub: lub zog pib txo qis dua 100 degree

Cryogenic Performance: Nce nce me ntsis hauv lub zog ntawm tsawg kub, tsis muaj kev hloov pauv

Cov khoom sib nqus: tsis sib nqus

Rov ua dua tshiab: 100% siv tau nrog cov nqi siab

Formancion: Zoo hauv T4 Taus, Txwv nyob rau hauv T6 Tauj

Qhov seem ruaj khov: zoo tshaj plaws hauv T651 / T6511 Tempers, haum rau precision machining

Lub zog-rau-hnyav piv: kom zoo dua nyob rau hauv cov ntawv thov kev siv

9. Kev paub tseeb & kev xeem

Cov Qauv Kuaj Cov Txheej Txheem:

Tshuaj lom neeg cov tshuaj:

Optical Opission Spectroscopy

X-Tshav Fluorescence tsom tsom Tsom

Cov ntaub ntawv pov thawj ntawm txhua qhov tseem ceeb thiab cov ntsiab lus los txawv

Kev Kuaj Neeg Kho:

Tensile kuaj (ntev thiab transverse)

Kev kuaj Hardness (Brinell, ntau qhov chaw)

Qaug zog xeem (raws li yuav tsum tau)

Nondestructive Testing:

Ultrasonic Soj ntsuam (100% Volumetric, ib astm B594 / E2375)

Eddy kev sim tam sim no (saum npoo thiab ze-nto tsis xws luag)

Kev kuaj xyuas tob tob (saum npoo tsis xws luag)

Microstructioning:

Grain Loj Kev Txiav Txim Siab

Nag lossis daus thiab kev ntsuam xyuas nruab nrab

Grain flow qauv pov thawj (rau forged bars)

Tshuaj Ntsuam Xyuas Sab Nrau:

CMM (koom ua ke ntsuas lub tshuab ntsuas)

Txoj kab uas hla, ntev, ncaj, ovality, thiab lwm yam {}

Qauv ntawv pov thawj:

Cov ntaub ntawv xeem ntawv tshaj tawm (en 10204 3.1 lossis 3.2)

Tshuaj Ntsuam Xyuas Tshuaj Txheeb Xyuas

Cov Khoom Siv Neeg Kho Tshuab Cov Khoom Siv

Kev Kho Cua Sov

Nondestructive Testioning Daim Ntawv Pov Thawj

Ua ywj pheej rau Astm B221 (ASTM B221 (ASTM B211 (rau Rolled / Txias-tiav Bar), lossis ASTM B247 (rau forged bar) raws li siv

10. Daim ntawv thov & Tsim Kev Txiav Txim

Thawj cov ntawv thov:

Cov Txheej Txheem Txheej Txheem:

Architecture Frames thiab txhawb nqa

Cov Cheebtsam Choj

Tsheb thiab Tubrog Nkoj

Automation Machinery Bases

Neeg kho tshuab qhov:

Valve Lub Cev, Twj Tso Kua Muag

Tsav Shafts, Zog

Bolts, neeg rau, fasteners

Jigs thiab fixtures

Kev Lag Luam Tsheb Thauj Mus Los:

Kev lag luam Automotive (chassis, tshem tawm)

Railwway Tsheb Cheebtsam

Tsheb kauj vab

Yact thiab nkoj Cheebtsam

Cov khoom siv hluav taws xob thiab cov khoom siv ntsuas hluav taws xob:

Khoom Siv Hluav Taws Xob

Hauv Tsev Hluav Taws Xob

Cov Khoom Siv Kho Mob Ntaus

Cov Khoom Siv Kho Qhov muag nkhaus

Cov Kev Ua Si thiab Cov Neeg Siv Khoom:

Nuv ntses reels

Ntaus Pob Ncaws Pob

Cov Duab Duab

Tsim Zoo:

Zoo tag nrho kev ua tau zoo: lub zog siab, corrosion tsis kam, yooj yim rau kev siv lub tshuab, weldable

Lub zog zoo-rau-nyhav piv rau hauv T6 npau taws

Tseem ceeb txhim kho kev txhim kho tom qab quenching thiab laus

Tsawg dawb tshuab distortion hauv T651 / T6511 Tempers

Yooj yim rau anodize thiab siv ntau yam kev kho cov npoo

Cov Kab Ntawv Vuam Zoo Tshaj

Zoo heev rau ntau yam kev lag luam

Tsis muaj sib nqus rau cov ntawv thov tshwj xeeb

Zoo rov qab

Kev txwv tsis muaj kev txwv:

Txo lub zog piv rau 7xxx series alloys

Corrosion tsis kam nyob rau hauv qee qhov chaw ua haujlwm marine tsis zoo li 5xxx series alloys

Tsis haum rau cov ntawv thov uas yuav tsum tau ua ultra-siab hardness thiab hnav tsis kam

Txwv siab-kub zog ua haujlwm (saum toj 150 degree)

Cov kev tsim cov peev xwm txias tsis zoo li alloys zoo li 5052

Lub zog hauv thaj chaw welded yuav tsawg dua

Kev Txiav Txim Siab Kev Lag Luam:

Kev ua tau zoo ntawm tus nqi tsim nyog, ua rau nws zoo tagnrho rau ntau daim ntawv thov

Dav siv cov saw hlau thiab cov peev txheej ntau lawm

Xws li cov nqi machining

Kev siv tau zoo tau txo cov nqi scrap

Kev Ncaj Ncees:

100% siv dua tshiab, cov peev txheej siab siv

Kev Siv Zog Quav Hluav Taws Xob hauv kev tsim khoom rau cov hlau

Kuj muaj cov kev cuam tshuam tsawg puag ncig thoob plaws nws kav

Lub neej ntev kev pabcuam txo qhov hloov zaus zaus

Ua raws li ROHS thiab mus txog tus qauv, pub dawb ntawm cov tshuaj muaj teeb meem

Cov Khoom Siv Xaiv Xaiv:

Xaiv 6061 thaum lub hom phiaj dav dav nrog lub zog siab, weldability zoo, thiab corrosion kuj xav tau

Xaiv 5052 thaum qhov kev ua kom muaj txiaj ntsig siab tshaj plaws thiab lub zog yog qhov tsawg dua

Xav txog 2xxx lossis 7xxx series alloys thaum ntau zog yog qhov tseem ceeb thiab muaj kev txhawj xeeb tseem ceeb

T6 Tauj yog haum rau feem ntau cov qauv kev tswj hwm thiab cov tshuab

T651 / T6511 Tempers tsim nyog rau qhov uas xav tau precision machining kev ntxhov siab

Cim npe nrov: 6061 Txoj kab loj loj Kab-Alloy Bar, Tuam Tshoj 6061 Txoj Kab Loj Loj

Xa kev nug