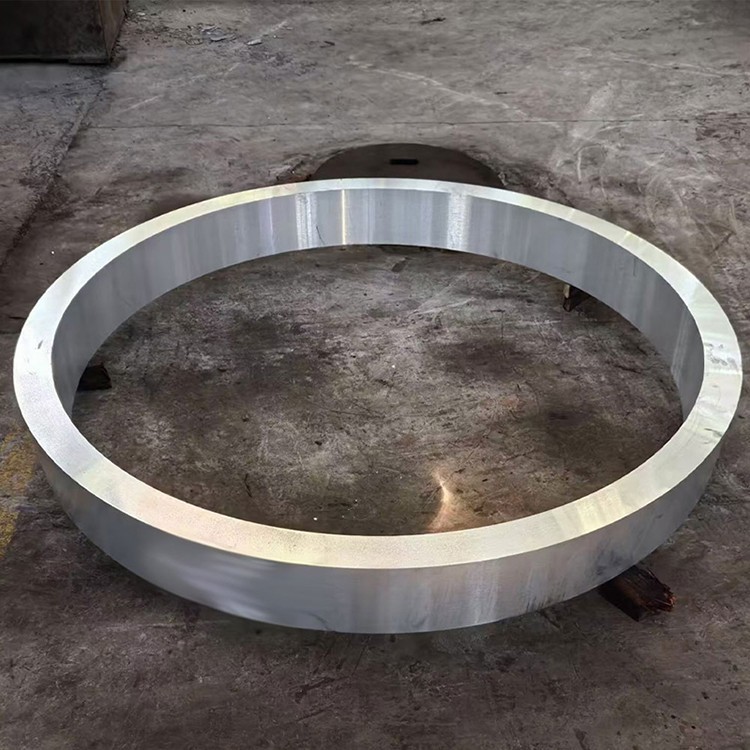

7075 T6 Aluminium Alloy Forging Nplhaib

7075 T6 Aluminoy Forged ntiv nplhaib yog qhov siab ua haujlwm txhuas, thiab muaj zog, thiab cov khoom siv hluav taws xob, thiab cov tshuab ua pa,} {}

1.}} cov khoom siv & cov txheej txheem tsim khoom

Qhov 7075 T6 Aluminium Alloy Alloy Txhaj Ntses nplhaib yog lub zog ultra-rau-qhov zoo forging rau cov ntaub ntawv thov kom muaj zog thiab Kev ntseeg tau, xws li aerospace, tiv thaiv, kev ua tau zoo machinery, thiab khoom siv siab:

Tseem Ceeb Alloying Ntsiab:

Zinc (ZN): {5.1-6.1% (thawj ntxiv dag zog ntxiv)

Magnesium (MG): {2.1-2.9% (cov ntaub ntawv ntxiv dag hluav taws xob nrog zinc)

Tooj (CU): 1.2-2.0% (txhim kho lub zog thiab hardness)

Chromium (CR): {0.18-0.28% (inhibits recrystallization, txhim kho kev ntxhov siab corrosion)

Cov khoom siv hauv paus:

Aluminium (Al): Tshuav

Kev tswj kev impurities:

Hlau (FE): Tsawg dua lossis sib npaug rau 0.50% Max

Silicon (si): tsawg dua lossis sib npaug rau 0.40% max

Manganese (MN): tsawg dua lossis sib npaug rau 0.30% Max

Titanium (ti): tsawg dua lossis sib npaug rau 0.20% Max

Lwm cov ntsiab lus: Tsawg dua lossis sib npaug rau 0.05% txhua, tsawg dua lossis sib npaug ntawm 0.15% tag nrho

Hwm Forging Txheej Txheem:

Kev npaj yaj:

High-purity thawj txhuas (99.7% yam tsawg kawg nkaus)

Kev tswj hwm kev tswj ntawm alloying cov ntsiab lus nrog ± 0.05% kev kam

Kev ua kom tau pom kev ua tiav thiab kev kho mob degassing (e {{{} g}, snif lossis nqus plua plav

Cov kws sau qoob loo (feem ntau nrog Al-ti-B tus tswv Alloy)

Direct-ntawj txias (DC) txuas ntxiv mus ua cov khoom lag luam zoo

Homogenization:

{{0 {}}℃rau 12-24 teev

Uniform kub tswj: ± 5 degree

KUB txias tus nqi xyuas kom ntseeg tau cov kev faib tawm ntawm cov ntsiab lus ntawm cov ntsiab thiab tshem tawm macro-soobration

Npaj nyiaj Billet:

Ingot nto txias (tawv taub hau lossis milling)

100% kev tshuaj xyuas kom ntseeg tau tias sab hauv flawlessness

Preheating: {{380-420 degree, nrog kev ntsuas kub ua kom haum

Forging Sequence (Nplhaib Forging):

Upsetting: Forging lub ingot rau hauv lub disk lossis preform nplhaib ntawm 380-420 degree

Tho / xuas nrig ntaus: tsim lub qhov nruab nrab uas siv nruab nrab kev tuag lossis mandrels, maj mam sib sau ua lub nplhaib zoo

Ntiv nplhaib dov: Siv lub nplhaib dov mus rau axially thiab radial nthuav lub nplhaib preform, ntxiv refining grain qauv thiab kev tswj hwm qhov ntev

Tuag forging ua tiav: kawg ntawm kev tuag los ua kom paub tseeb geometric precision thiab nto tas

Forging Kub: {350-400℃(precisely tswj qab recrystallization kub)

Forging Siab: Ntau txhiab rau kaum tawm txhiab tus tons, nyob ntawm cov nplhaib loj thiab cov nyom

Cov qauv txo qis kawg nkaus: 4: 1 txog 6: 1, kom muaj kev sib txawv ntawm cov qauv cam, thiab tsim ntawm cov lis kom zoo

Tshuab Kev Kho Mob Kub:

{{0465-480℃rau 1-4}} sijhawm (nyob ntawm cov nplhaib phab ntsa tuab)

Cov ris tsho kub: ± 3 degree

Hloov pauv sai sai (<10 seconds)

Quenching:

Dej queny (chav sov lossis dej kub) lossis polymer quench

Kev tswj cov nqi txias kom ua tiav cov muaj zog thiab tawv

Kev nyuaj siab nyem (rau T651 Tauj):

Kev tswj ncab ({1-3}}% deformation) lossis compression kom txo qis kev ntxhov siab

Kev laus cuav (T6 npau taws):

120 Qib rau 24 teev

Txhua theem ntau lawm yog kev kawm nruj nruj kev tswj hwm, tsis yog kev tswj hwm kev ua phem, thiab kev tswj hwm tsheb ciav hlau.

{{02. i} Cov Khoom Siv Neeg Kho Tshuab 7075 T6 Forging nplhaib

|

Ntiag tug |

T6 |

T651 |

Txoj kev xeem |

|

Qhov kawg tensile lub zog |

540-590 mpa |

540-590 mpa |

ASTM E8 |

|

Tos lub zog (0.2%) |

480-530 mpa |

480-530 mpa |

ASTM E8 |

|

Elongation (2 nti) |

7-11% |

7-11% |

ASTM E8 |

|

Hardness (Brinell) |

150-165 hb |

150-165 hb |

Astm E10 |

|

Qaus zog zog (5 × 10⁷ mus) |

160-180 mpa |

160-180 mpa |

ASTM E466 |

|

Tawv muaj zog |

330-360 mpa |

330-360 mpa |

ASTM B769 |

|

Kev ua kom nruj (K1c, raug) |

22-28 mpa√m |

22-28 mpa√m |

ASTM E399 |

Vajtsoob:

Radial vs . Cov khoom siv tau zoo tshaj plaws ntawm kev ua kom zoo dua qub (muaj cov khoom siv tsis zoo.

Phab Ntsa Thickness nyhuv rau cov khoom: lub zog yuav nce me ntsis nce ntxiv hauv thinner phab ntsa ntu {}}

Tub ntxhais mus rau saum npoo hardness variation: tsawg dua 5 hb .

Kev ntxhov siab nyob rau: T651 Tem tau txo cov kev ntxhov siab uas txo qis kev ntxhov siab los ntawm kev nyuaj siab kev kho mob, txo cov tshuab ua kom zoo nkauj.

Kev ua tau zoo: optimized nplej tsim los ntawm kev forging cov txheej txheem txhim kho cov khoom siv nkees nkees tshaj tawm {}}

3.} microstructural yam ntxwv

Qhov Tseem Ceeb Microstructural nta:

Grain qauv:

Nplua, hnav cov khoom siv sib xyaw ntawm cov nplej recrystallized thiab elongated tsis-recrystallized nplej ua kom haum rau cov nplej ua kom haum

Grain flowly sib phim nrog lub nplhaib lub geometry, uniformly faib tangentently, maximizing kev ua tau zoo

Al₁₈mG₃crr₂ Dispersids tsim los ntawm Chromium Zoo Zoo Inhibit Gragit Kev Loj Hlob thiab Recrystallization

ASTM grain loj 6-9 (45-16 μm)

Precipition faib:

η '(mgzn₂) thiab η (mgzn₂) theem: theem disiformed, muab cov khoom muaj ntxiv dag zog ntxiv

Kev sib zog ua ntej ntawm mgzn₂ ntawm cov ciaj ciam nplej tswj tau los txo cov kev ntxhov siab corrosion rhiab

Kev sib xyaw ua ke sib txuas lus sib xyaw ua ke los ntawm cov me Fe, SI yog qhov tawg tau zoo thiab tawg

Kev Kawm Ntawv:

Forging cov txheej txheem tsim tshwj xeeb cov ntsiab lus muaj txiaj ntsig zoo rau cov thaj chaw tangerial

Cov Nta Tshwj Xeeb:

Siab metallurgical huv si, txo cov xim tsis sib xws

Nruj me ntsis cov hmoov nplej zinc-depleted chaw dav thiab kev ua daus tsis tu ncua yog qhov tseem ceeb yog qhov tseem ceeb rau SCC Kuj

4.} Qhov ntev tshaj tawm & kev thev taus

|

Chaw ua uas tsis tau haus |

Cov Qauv Qeb |

Precision Kev Zam |

Kev Lag Luam Ua Lag Luam |

Txoj kev xeem |

|

Txheej hauv lub taub |

100-1500 hli |

± 0.5mm txog 500 hli |

± 1.0mm txog 500 hli |

Micrometer / CMM |

|

± 0.1% 500 hli |

± 0.2% tshaj 500 hli |

|||

|

Sab hauv Inch |

80-1400 hli |

± 0.5mm txog 500 hli |

± 1.0mm txog 500 hli |

Micrometer / CMM |

|

± 0.1% 500 hli |

± 0.2% tshaj 500 hli |

|||

|

Phab Ntsa Thickness |

10-300 hli |

± 0.2 hli |

± 0.5 hli |

Micrometer / CMM |

|

Qhov siab |

20-500 hli |

± 0.2 hli |

± 0.5 hli |

Micrometer / CMM |

|

Huv |

N/A |

0.1mm / 100 hli lub taub |

0.2 hli / 100 hli lub taub |

Flawe Gauge / CMM |

|

Kev Pom Zoo |

N/A |

0.1mm |

0.2 hli |

Lub koob yees duab / cmm |

|

Nto roughness |

N/A |

3.2 μm RA Max |

6.3 μm RA Max |

Profat |

Qauv muaj cov qauv:

Forged Rings: Txheej Inch 100mm rau 1500mm, Phab Ntsa Thickness 10mm rau 300mm

Kev cai loj thiab geometries muaj raws li cov neeg siv khoom lag luam thiab cov kev xav tau

Ntau yam machining tej yam muaj, e {. g}}}}}}, forged li-yog, ntxhib machined, tiav machined

5.}}}}} Kev Kho Mob Cua Sov

|

Tauj Ntshav |

Kev piav qhia cov txheej txheem |

Qhov Zoo Tshaj Ntawv |

Cov yam ntxwv tseem ceeb |

|

T6 |

Daws cov tshuaj tiv thaiv tshav kub thiab muaj zog |

Ntau lub zog, cov txheej txheem dav dav |

Lub zog siab tshaj plaws, tab sis ntau dua Scc rhiab rhiab |

|

T651 |

T 6 + kev nyuaj siab relieved los ntawm ncab |

Cov txheej txheem tseem ceeb, tsis muaj kev ntxhov siab tsawg |

Lub zog siab, qhov zoo tshaj plaws ruaj ruaj ruaj ruaj, qis machining distortion |

|

T73/T7351 |

Kev daws teeb meem thaum tshav kub kho tau + Ofaged kho |

Cov ntawv thov yuav tsum tau ua Super Super SCC tsis kam |

Me ntsis qis zog, tab sis zoo scc kuj |

|

T7451 |

Kev daws teeb meem kub kho tau + ob-theem hla |

Sib npaug ntawm lub zog thiab Scc Kuj |

Siab dua lub zog tshaj T73, zoo heev SCC tiv |

Cov Lus Taw Qhia Txog Kev Xaiv Tsa:

T6: Thaum xav tau lub zog siab tshaj plaws thiab ib puag ncig mob tsis hnyav, lossis rau cov nplhaib tuab tuab tsis nkag siab rau scc

T651: Thaum lub zog siab yog xav tau, thiab lub nplhaib yuav yauv tsis muaj qhov tseem ceeb precision machising tshuab los txo distortion

T73 / T7351: Thaum lub nplhaib yuav ua haujlwm hauv cov chaw muaj kev ua kom muaj zog thiab yuav tsum muaj cov Scc tsis tshua muaj, ntawm cov nuj nqis ntawm qee lub zog

Lub T6 npau npau ntawm 7075 alloy muaj qee qhov kev paub txog SCC. Tus lej fishing, muaj kev sib cuam tshuam nrog cov nplej zoo {}}

6. tshuab machining & Fabrication tej yam

|

Kev phais |

Lub cuab yeej |

Pom zoo tsis |

Lus |

|

Txoj siav |

Carbide, pcd |

VC =100-300 m / min, f =0.1-0.3 hli / rev |

Kev nrawm nrawm rau kev nrawm rau zoo heev ua tiav, saib xyuas kom tawg |

|

Kev drilling |

Carbide, Tin coated |

VC =50-120 m / min, f =0.08-0.2 hli / rev |

Los ntawm kev ua kom tiav cov dej uas tau pom zoo, tob lub qhov drilling yuav tsum tau saib xyuas kom pom cov nti |

|

Milling |

Carbide, hss |

VC {=150-500 m / min, fz =0.05-0.15 hli |

High-ins lub kaus sab lub kaum sab xis, loj tob ntawm kev txiav, siab noj |

|

Tab tom |

Hss-e-pm, ticn coated |

Vc =10-20 m / min |

Lub cev kom haum rau cov xov zoo |

|

Kev sib tsoo |

Txhuas oxide, cbn log |

Siv nrog ceev faj, tuaj yeem ua rau muaj kev ntxhov siab saum npoo thiab seem |

Kev tswj nruj ua kom tsis muaj qhov tsis sib xws thiab txias yog tias tsim nyog |

|

Polishing |

Mos log, ua kom tiav zaub mov nplaum |

Txhim kho saum npoo tiav, txo cov kev ntxhov siab |

Huv si saum npoo tom qab polishing |

Kev Taw Qhia Fabricance:

Luam Ntawv Ntsuas: 40% (1100 Txhuas= 100}}}}}}}}}

Nti Ua Tsim: Tas rau daim ntawv nplua, tawg cov chips, tab sis cua sov conventration thiab yuav tsum tau zoo nti khiav tawm thiab txias

Coolant: Dej-soluble txiav kua (10-15}% concentration), siab ntws tus nqi cua txias; Cov roj txiav roj av kuj tseem siv tau

Tuam Kev Hnav: Siab, Pom zoo kom PCD lossis coated carbide cov cuab yeej, kev tshuaj xyuas ib txwm

Weldability: Tsis Zoo, Kev Pom Zoo Vuam tsis pom zoo, txwv rau cov txheej txheem tshwj xeeb xws li kev sib txhuam, nrog lub zog tseem ceeb tom qab vuam

Cov Haujlwm Txias: Tsis tsim nyog los formability, tsis haum rau txias dabtsi yog khoov, stamping, etc {{{{{{{{{{{{{{{{{{}

Kub Ua hauj lwm: Forging yuav tsum tau ua nyob rau hauv nruj me ntsis tswj kub thiab lim tus nqi

Kev kho deg: tuaj yeem yog anodized (sulfuric anodization pom zoo), tab sis tsis cuam tshuam dab tsi SCC rhiab heev .

{{07. corrosion Kuj & Kev Tiv Thaiv Cov Tshuab

|

Ib puag ncig hom |

Kev Ntsuas |

Kev Tiv Thaiv Txoj Kev |

Kev cia siab |

|

Muaj cua |

Zoo |

Anodizing + Sealing |

5-10 xyoo |

|

Marine cua |

Ncaj |

Anodizing + Sealing / Painting |

2-5 xyoo |

|

Dej hiav txwv immersion |

Pluag |

Nruj txheej txheej system, lossis cladding |

Nyob ntawm txheej zoo thiab txij nkawm |

|

Siab vaum |

Zoo |

Anodizing + Sealing |

5-10 xyoo |

|

Kev ntxhov siab corrosion |

Ncaj ncees (T6 Tauj) |

T73 / T74 Tempers, lossis Tiv Thaiv Txheej |

T6 Tem Taw yog rhiab, T73 / T74 muaj kev tiv thaiv zoo heev |

|

Kho |

Ncaj ncees (T6 Tauj) |

T76 Tauj Ntshav, lossis Tiv Thaiv Txheej Txheem |

T6 Tem Taw yog rhiab, T76 muaj kev tiv thaiv zoo heev |

|

Galvanic corrosion |

Zoo |

Kom muaj kev sib cais |

Ceev faj tsim nrog cov sib luag |

Kev Xaiv deg Nto:

Anodizing:

Hom II (Sulfuric): {{{{{}} μm thickness, txhim kho kev hnav thiab corrosion tsis kam, tuaj yeem ua kom tau

Hom III (nyuaj): {25-75 μm thickness, rau cov ntaub ntawv loj

Kev hloov dua tshiab txheej:

SROMATE hloov txheej txheej (mil-dtl -5541}}}}}}}}

Kev Xaiv Cov Chromium-Dawb: Ib puag ncig raws li

Lub tshuab tha xim:

Epoxy Primer + Polyurethane Topcoat: muab kev tiv thaiv ntev ntev, tshwj xeeb rau cov neeg ua haujlwm hauv aerospace thiab tub rog

Cladding:

Nyob rau hauv huab corrosive ib puag ncig, cladging ib puag ncig corrosive puag ncig, corrosion-resistant alloy txheej yuav raug txiav txim siab, tab sis ntxiv qhov hnyav thiab nqi

{{08. Cov Khoom Siv Rau Lub Cev Rau Cov Kws Tsim Khoom Lag Luam

|

Ntiag tug |

Tus nqi |

Tsim Kev Txiav Txim Siab |

|

Ceev |

2.81 g / cm³ |

Kev ntsuas hnyav thiab cov qauv kev ua kom zoo |

|

Melting ntau |

477-635 degree |

Cua sov kho qhov rai thiab vuam txwv |

|

Thermal conductivity |

130 W/m·K |

Kev tswj hwm cua sov, kev hloov pauv kub |

|

Hluav Taws Xob Kev Tshaj Tawm |

33% IACS |

Hluav Taws Xob Kev Siv Hluav Taws Xob |

|

Cov cua sov tshwj xeeb |

860 J / Kg · K |

Thermal Mass thiab cua kub muaj peev xwm |

|

Thermal Expansion (CTE) |

23.4 ×10⁻⁶/K |

Kev hloov sab nraud vim yog qhov kub hloov pauv |

|

Cov tub ntxhais hluas lub modulus |

71.7 GPA |

Deflection thiab stiffness suav |

|

Poisson tus piv |

0.33 |

Cov Txheej Txheem Ntsuam Xyuas Parameter |

|

Damping muaj peev xwm |

Nruab nrab-qis |

Kev co thiab suab nrov tswj |

Kev txiav txim siab tsim:

Kev Ua Haujlwm Kub Ntau Yam: {-60℃rau +100℃(muaj zog ntau dua qhov no)

Cryogenic Performance: Nce nce me ntsis hauv lub zog ntawm tsawg kub, tawv tseem zoo, tsis muaj nkig hloov pauv

Cov khoom sib nqus: tsis sib nqus

Rov qab siv dua: Cov khoom siv tau muaj txiaj ntsig zoo

Qhov seem ruaj khov: Zoo heev hauv T651 Tauj, Haum rau qhov machising machising

Lub zog-qhov hnyav piv: Ntawm qhov siab tshaj plaws rau aluminium alloys, zoo tagnrho rau Aerospace cov ntaub ntawv

9. Kev paub tseeb & kev xeem

Cov Qauv Kuaj Cov Txheej Txheem:

Tshuaj lom neeg cov tshuaj:

Optical Opission Spectroscopy

Inert gas fusion (hydrogen cov ntsiab lus)

Cov ntaub ntawv pov thawj ntawm tag nrho cov khoom siv thiab cov ntsiab lus tsis sib haum

Kev Kuaj Neeg Kho:

Tensile Testing (radial, tangent, axial)

Kev kuaj Hardness (Brinell, ntau qhov chaw)

Kev sim ua nruj ua ke (K1C, ib astm E399)

Qaug zog xeem (raws li yuav tsum tau ua, e {{{0} g .}, tig los ntawm kev qaug zog nkees, khiav ceev tus nqi)

Kev ntxhov siab corrosion tsoo kev sim (SCC, ib antm G44, G47), tshwj xeeb tshaj yog rau T6 Tauj

Nondestructive Testing:

Ultrasonic Soj ntsuam (100% Volumetric, ib tshooj 1130 chav kawm A1, AMS-STD -2154, lossis ast 2375 qib 2)

Eddy kev sim tam sim no (saum npoo thiab ze-nto tsis xws luag)

Kev kuaj xyuas tob tob (saum npoo tsis xws luag)

TradiGraphic Xeem (Sab Hauv Macroscopic tsis xws luag)

Microstructioning:

Grain Loj Kev Txiav Txim Siab

Grain flow qauv pov thawj

Kev ntsuam xyuas precipitate (DEM / SEM)

Kev Ntsuam Xyuas Kev Ntsuas DuaTus

Tshuaj Ntsuam Xyuas Sab Nrau:

CMM (koom ua ke ntsuas lub tshuab ntsuas)

Txheej txheej uas hla, sab hauv lub taub, phab ntsa tuab, qhov siab, fav txhua yam, thiab lwm yam.

Qauv ntawv pov thawj:

Mill Xeem Ntawv Tshaj Qhia (en 10204 3.1 lossis 3.2)

Tshuaj Ntsuam Xyuas Tshuaj Txheeb Xyuas

Cov Khoom Siv Neeg Kho Tshuab Cov Khoom Siv

Kev Kho Cua Sov / Forging Daim Ntawv Pov Thawj

Nondestructive Testioning Daim Ntawv Pov Thawj

Kev ywj pheej rau Ams 4133 (STRING Forgings), Ams 4145, ASTM B247 (Kev Zam Txim), thiab lwm yam qauv AERPOOPACE

AS9100 lossis ISO 9001 Kev Tswj Xyuas Kev Tswj Xyuas Zoo

10. Daim ntawv thov & Tsim Kev Txiav Txim

Thawj cov ntawv thov:

Aerospace:

Cav ntoo txua lub cim, qhia vane ib ncig

Cov dav hlau dav dav hlau Cheebtsam

Tsaws Cov Duab Iav Txuas Txuas

Cov foob pob hluav taws thiab Missile casing rings

Defense:

Tub rog tsheb Turret Rings

Phom Turret Bases

High-siab txog ntsha

Kev ua haujlwm siab Machinery:

Cov kabmob hnyav Machinery hnyav

Kev Ntsuas Cov Khoom Kub Ceev Cav

Precision twj cuab yeej cuab yeej

Cov Khoom Siv Industrial:

Roj thiab Roj Drilling Cov Khoom Siv Hluav Taws Xob

Li qub thiab flanges

Tsim Zoo:

Tsis tshua muaj zog-rau-qhov hnyav piv rau kev tsim hnav

Forging cov txheej txheem tsim kom zoo Grain, txhim kho kev qaug zog zoo thiab ua kom muaj zog

Zoo Machine (txheeb ze rau lwm ultra-siab lub zog steels)

Kev tsis muaj kev ntxhov siab qis hauv T651 Tauj, Kev ruaj khov sab ruaj khov, haum rau qhov kev sib nraus tshwj xeeb

Tsis muaj hlau nplaum

Kev txwv tsis muaj kev txwv:

T6 Tlim muaj qee qhov rhiab heev rau kev ntxhov siab corrosion (SCC) thiab exfoliation corrosion; Rau cov ntawv tseem ceeb, cov cim sib txuam zoo li T73, T74 yuav tsum tau txiav txim siab

Heev tsis zoo weldability, kev pom zoo vuam tsis pom zoo

Lub cev tsis zoo, feem ntau tsim hauv annealed mob

Cov kub kub tsis zoo, kev ua tau zoo degrades sai sai ntawm ntug dej kub

Kuj raug nqi ntau

Kev Txiav Txim Siab Kev Lag Luam:

7075 T6 Forged Rings yog cov khoom siv siab, nrog cov nqi siab dua qub

Forging, kev kho cua sov, thiab kuaj cov txheej txheem ntxiv rau cov nqi ntau lawm

Txawm hais tias tus nqi siab, nws superiority ua rau nws irreplacable hauv cov ntawv thov thiab kev ntseeg tau

Kev Ncaj Ncees:

7075 alloy yog cov khoom siv rov ua dua, ua rau muaj cov khoom siv hluav taws xob

Kev Tsim Kev Tsim hauv Aerospace pab txo cov roj noj thiab cov pa roj carbon

Ntev cov khoom lag luam nyiaj thiab kev ntseeg siab txo qis thiab khib tiam

Cov Khoom Siv Xaiv Xaiv:

Choose 7075 T6 forged rings when maximum strength and lightweight are required, and the service environment is non-corrosive, or effective protection measures are in place

Haum rau lub nplhaib-puab cov txheej txheem sib xyaw ua ke kom muaj kev ntxhov siab, kev qaug zog, thiab xav tau kev ntseeg siab

Rau cov ntawv thov muaj peev xwm ua rau muaj kev ntxhov siab lossis kev pheej hmoo corrosion, ua ntej muaj ntau yam ntawm 70}} ..., t74) lossis 7050 alloy

Cim npe nrov: 7075 T6 Aluminium Alloy Alloy Alloy Forging nplhaib, Tuam Tshoj 7075 T6 Aluminium Alloy Forging Nplhaib Chaw Tsim Tshuaj, Chaw muag khoom, Hoobkas

Xa kev nug