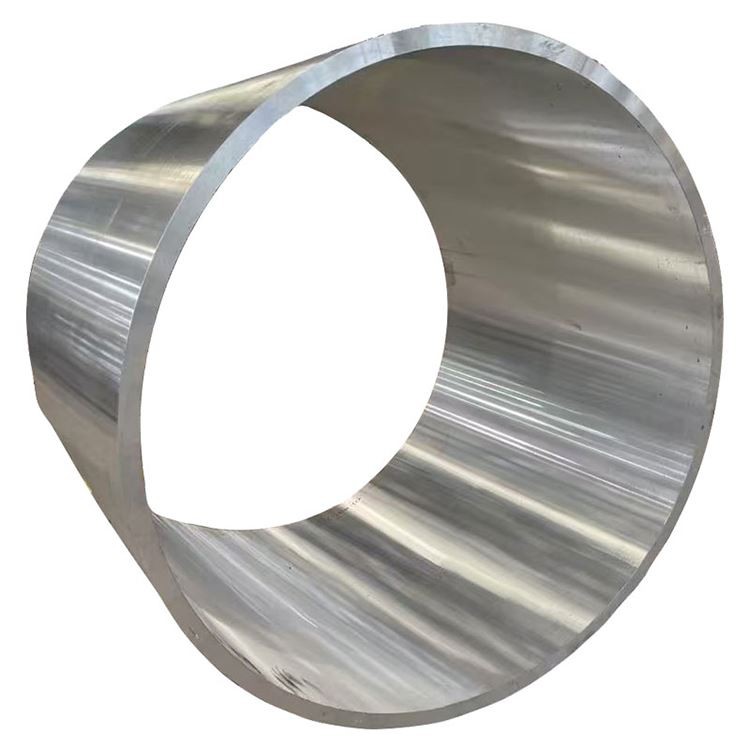

5A06 H112 Txhuas Ntses Forged Ntiv Nplhaib

5A06 H112 Txhuas Forged ntiv nplhaib yog lub luag haujlwm tseem ceeb hauv ntau lub zog, thiab yooj yim ntawm kev ua {}}

1.}} cov khoom siv & cov txheej txheem tsim khoom

5A06 H112 Txhuas Ntses Forged Ntiv nplhaib yog lub siab-zog, tshwj xeeb} Lub zog ntawm H112 Tshaj Plaws Ceev cia nws forged microstructure thiab qee qhov kev xaiv forget, ua rau cov ntaub ntawv forging zoo tshaj plaws, nws cov khoom lag luam tawm tsam, thiab cov khoom siv tsis zoo, thiab cov hlab ntsha cryogenic, thiab cov hlab ntsha cryogenic, thiab cov hlab ntsha

Tseem Ceeb Alloying Ntsiab:

Magnesium (MG): {{5.8-6.8% (thawj ntxiv dag zog, muab lub zog siab thiab zoo weldability)

Manganese (MN): {0.5-0.8% (ntxiv kom muaj zog thiab rov qab tuav)

Chromium (CR): {0.10-0.20% (inhibits recrystallization, txhim kho kev ntxhov siab corrosion)

Titanium (ti): 0.02-0.10% (grain refinement)

Cov khoom siv hauv paus:

Aluminium (Al): Tshuav

Kev tswj kev impurities:

Hlau (FE): Tsawg dua lossis sib npaug rau 0.25% Max

Silicon (si): tsawg dua lossis sib npaug rau 0.40% max

Tooj liab (Cu): tsawg dua los yog sib npaug rau 0.10% Max

Zinc (Zn): Tsawg dua lossis sib npaug rau 0.20% Max

Beryllium (yuav): 0.0001-0.005% (inhibits oxidation)

Lwm cov ntsiab lus: Tsawg dua lossis sib npaug rau 0.05% txhua, tsawg dua lossis sib npaug ntawm 0.15% tag nrho

Hwm Forging Txheej Txheem:

Kev npaj yaj:

High-purity thawj txhuas

Kev tswj hwm kev tswj ntawm alloying cov ntsiab lus nrog ± 0.05% kev kam

Kev kho kho kom pom tseeb thiab kev kho mob degassing (e {{{{} g}, snif lossis qeeb degsary

Cov kws sau qoob loo (feem ntau nrog Al-ti-B tus tswv Alloy)

Direct-ntawj txias (DC) txuas ntxiv mus ua cov khoom lag luam zoo

Homogenization:

{{0 {}}℃rau 8-16 teev

Uniform kub tswj: ± 5 degree

Ua kom muaj kev faib tawm ntawm cov ntsiab lus ntawm cov ntsiab lus thiab tshem tawm cov kab mob me

Npaj nyiaj Billet:

Ingot nto txias (tawv taub hau lossis milling)

Kev kuaj ultrasonic kom ntseeg tau tias sab hauv flawlessness

Preheating: {{380-420 degree, nrog kev ntsuas kub ua kom haum

Forging Sequence (Nplhaib Forging):

Upsetting: Forging lub ingot rau hauv lub disk lossis preform nplhaib ntawm 380-420 degree

Tho / xuas nrig ntaus: tsim lub qhov nruab nrab uas siv nruab nrab kev tuag lossis mandrels, maj mam sib sau ua lub nplhaib zoo

Ntiv nplhaib dov: Siv lub nplhaib dov mus rau axially thiab radial nthuav lub nplhaib preform, ntxiv refining grain qauv thiab kev tswj hwm qhov ntev

Tuag forging ua tiav: kawg ntawm kev tuag los ua kom paub tseeb geometric precision thiab nto tas

Forging Kub: 350-400 degree

Forging Siab: Ntau txhiab ntawm tons, nyob ntawm lub nplhaib loj thiab cov nyom

Cov qauv txo qis kawg nkaus: 3: 1 txog 5: 1, ua kom muaj kev sib tw sab hauv, thiab tsim cov xees uas tau txaus

Annaling (xaiv tau):

Yog tias yuav tsum tau ua ntxiv lossis kev hloov kho microstration, annealing tuaj yeem ua tom qab kev zam txim kom ua tiav qhov kev npau taws kom ua tiav qhov kev npau taws.

H112 Tauj Tsim:

Tom qab forging, cov khoom undergoes tsuas yog kev ua haujlwm me me (yog tias xav tau ntxiv kev kho mob lossis ncaj qha ua haujlwm sov lossis ua haujlwm txias {}

Txhua theem ntau lawm yog kev kawm nruj nruj kev tswj hwm, tsis yog kev tswj hwm kev ua phem, thiab kev tswj hwm tsheb ciav hlau.

{{02.} cov khoom siv mechanical ntawm 5A06 h112 forged nplhaib

|

Ntiag tug |

H112 |

Txoj kev xeem |

|

Qhov kawg tensile lub zog |

300-340 mpa |

ASTM E8 |

|

Tos lub zog (0.2%) |

150-180 mpa |

ASTM E8 |

|

Elongation (2 nti) |

16-22% |

ASTM E8 |

|

Hardness (Brinell) |

70-85 hb |

Astm E10 |

|

Qaus zog zog (5 × 10⁸ mus) |

120-150 mpa |

ASTM E466 |

|

Tawv muaj zog |

170-200 mpa |

ASTM B769 |

|

Kev ua kom nruj (K1c, raug) |

28-35 mpa√m |

ASTM E399 |

Vajtsoob:

Radial vs . Cov khoom lag luam zoo tshaj plaws (muab cov qoob loo txaus), muab cov qoob loo ntws tawm ntawm cov khoom siv zoo heev (muaj zog ntau dua .

Phab Ntsa Thickness nyhuv rau cov khoom: lub zog yuav nce me ntsis nce ntxiv hauv thinner phab ntsa ntu {}}

Tub ntxhais mus rau saum npoo hardness variation: tsawg dua 5 hb .

Residual kev ntxhov siab: H112 TaG tau txais qee qhov kev ntxhov siab ntawm kev zam txim; Yog hais tias rhiab rau kev txhawj xeeb yog qhov kev txhawj xeeb yog qhov kev txhawj xeeb, kev ua haujlwm tom ntej yuav xav tau kev ntxhov siab nyem {}}

Cov kev ua tau zoo: Optimized nplej forged tsim los ntawm kev forging process thiaj pab txhim kho cov khoom siv lub neej qaug zog {}}

Cryogenic Performance: Lub zog thiab tawv txawm tau txhim kho hauv qhov chaw qis qis, nrog tsis muaj cov khoom siv tsis muaj tseeb, ua rau muaj cov txheej txheem cryogenic zoo nkauj

3.} microstructural yam ntxwv

Qhov Tseem Ceeb Microstructural nta:

Grain qauv:

Nplua, hnav cov khoom siv sib xyaw ntawm cov nplej recrystallized thiab elongated tsis-recrystallized nplej ua kom haum rau cov nplej ua kom haum

Grain flowly sib phim nrog lub nplhaib lub geometry, uniformly faib tangentently, maximizing kev ua tau zoo

Cov nplua tawg ua los ntawm manganese (mn), chromium (CR), thiab titanium (ti) zoo inhibit qoob loo loj hlob thiab recrystallization

ASTM grain loj 6-9 (45-16 μm)

Precipition faib:

-Muaj -maleal₈ theem: nplua thiab uniformly dispersed, ua yeeb yam raws li thawj lub peev xwm txhim kho theem

MG-Al Intermetallic cov tebchaw: Cov lus faib ntawm cov ciaj ciam av tau tswj kom tsis txhob muaj kev ntxhov siab corrosion rhiab

Cov nyiaj me me ntawm thawj cov kev sib txuas ua ke sib txuas zoo li Alfemnats tau tawg ua kom zoo thiab tawg

Kev Kawm Ntawv:

Forging cov txheej txheem tsim tshwj xeeb cov ntsiab lus muaj txiaj ntsig zoo rau cov thaj chaw tangerial

Cov Nta Tshwj Xeeb:

Siab metallurgical huv si, txo cov xim tsis sib xws

Kev tswj cov dej nag tsis tu ncua ntawm beta-theem ntawm cov ciaj ciam kev txhim kho corrosion tsis kam

4.} Qhov ntev tshaj tawm & kev thev taus

|

Chaw ua uas tsis tau haus |

Cov Qauv Qeb |

Precision Kev Zam |

Kev Lag Luam Ua Lag Luam |

Txoj kev xeem |

|

Txheej hauv lub taub |

100-2000 hli |

± 0.8mm txog 500 hli |

± 1.5mm txog 500 hli |

Micrometer / CMM |

|

± 0.2% tshaj 500 hli |

± 0.4% saum 500 hli |

|||

|

Sab hauv Inch |

80-1900 hli |

± 0.8mm txog 500 hli |

± 1.5mm txog 500 hli |

Micrometer / CMM |

|

± 0.2% tshaj 500 hli |

± 0.4% saum 500 hli |

|||

|

Phab Ntsa Thickness |

10-400 hli |

± 0.5 hli |

± 1.0mm |

Micrometer / CMM |

|

Qhov siab |

20-600 hli |

± 0.5 hli |

± 1.0mm |

Micrometer / CMM |

|

Huv |

N/A |

0.2 hli / 100 hli lub taub |

0.4mm / 100mm lub taub |

Flawe Gauge / CMM |

|

Kev Pom Zoo |

N/A |

0.2 hli |

0.4mm |

Lub koob yees duab / cmm |

|

Nto roughness |

N/A |

6.3 μm RA Max |

12.5 μm ra max |

Profat |

Qauv muaj cov qauv:

Forged ib ncig: txheej inch 100mm rau 2000mm, Phab Ntsa Thickness 10mm txog 400MM

Kev cai loj thiab geometries muaj raws li cov neeg siv khoom lag luam thiab cov kev xav tau

Ntau yam kev ua tau zoo muaj, e {{{0} g .}}, forged li-yog, ntxhib machined

5.}}}} kev xaiv ua haujlwm Hardening Hardening Harden

|

Tauj Ntshav |

Kev piav qhia cov txheej txheem |

Qhov Zoo Tshaj Ntawv |

Cov yam ntxwv tseem ceeb |

|

O |

Tag nrho anealed, muag muag |

Cov ntawv thov yuav tsum muaj qhov siab tshaj plaws, lossis ua kom tob tob |

Qhov siab tshaj plaws ductility, qis tshaj lub zog |

|

H111 |

Muaj mob tawv tawv tawv tom qab tag nrho annealing |

Cov qauv dav dav, zoo heev tom qab-weld Khoom |

Kev sib npaug zoo ntawm lub zog thiab ductility |

|

H112 |

Pluav ib zaug ntxiv tom qab forging |

Haum rau kev ua ua ntej ua ntej kev siv lub tshuab, nrog rau cov kev ntxhov siab uas muaj kev ntxhov siab |

Raws li-forged mob, nruab nrab lub zog, zoo heev corrosion tsis kam |

|

H321 |

Ruaj Ruaj H32 Tauj |

Lub zog siab, nruj strictt corrosion tiv thaiv |

Zoo heev Scc tsis kam, lub zog siab dua |

Cov Lus Taw Qhia Txog Kev Xaiv Tsa:

H112: Thaum siv cov microstration microstructure thiab cov zog, thiab kev ua ntxiv yog xav tau.

O: Thaum ua haujlwm txias ua haujlwm lossis qhov siab tshaj plaws yog xav tau rau lub nplhaib .

H111: Thaum siab dua H112 yuav tsum muaj, thaum tswj hwm kev ua kom zoo thiab weldability.

H321: Thaum tseem ceeb heev rau corrosion tsis kam (tshwj xeeb yog kev nyuaj siab corrosion tawg) tam sim no, nrog rau lub zog siab dua xav tau.

Raws li al-mg series alloy, 5A06 tsis yog ntxiv dag zog los ntawm kev kho cua sov; Cov Tempers sib txawv yog qhov ua tiav tau los ntawm kev ua haujlwm txias.}}}} sawv cev rau cov kev mob yas ua kom zoo li-forged mob.

6. tshuab machining & Fabrication tej yam

|

Kev phais |

Lub cuab yeej |

Pom zoo tsis |

Lus |

|

Txoj siav |

Carbide, pcd |

VC =150-400 m / min, f =0.1-0.4 hli / rev |

Yooj yim kom ua tiav qhov chaw zoo tiav, muaj qhov cuab yeej siv hluav taws xob |

|

Kev drilling |

Carbide, Tin coated |

VC =60-150 m / min, f =0.15-0.35 hli / rev |

Los ntawm kev ua kom tiav txoj kev ua kom tau zoo, zoo rau qhov tob qhov |

|

Milling |

Carbide, hss |

VC {=200-600 m / min, fz =0.1-0.25 hli |

High-ins lub kaus sab lub kaum sab xis, loj tob ntawm kev txiav, siab noj |

|

Tab tom |

Hss-e-pm, ticn coated |

Vc =15-30 m / min |

Lub cev kom haum rau cov xov zoo |

|

Tus rov ua dua |

Carbide, hss |

VC =50-100 m / min, f =0.2-0.5 hli / rev |

H7 / H8 zam kev ua tiav |

|

Sawing |

Carbide-Tipped Hniav |

Vc =800-2000 m / min |

Siv tau tej txoj kab uas loj loj loj |

Kev Taw Qhia Fabricance:

Luam Ntawv Ntsuas: 70% (1100 Txhuas= 100}}}}}} dua 2xxx thiab 7xxx alloys

Ntsis tsim: Cov chips gummy, zoo li qhwv ib ncig twj, yuav tsum tau txais cov cheem zoo

Coolant: Dej-Soluble Txiav Kua ({1}}}% concentration), siab ntws tus nqi cua txias

Tuam Khoom Hnav: Nruab nrab, xav tau kev soj ntsuam cov cuab yeej siv

Weldability: Zoo heev nrog Tig thiab Mig Vuam, yog ib qho zoo tshaj plaws weldable aluminium alloys

Cov haujlwm txias: Kev tsim kho zoo hauv O Tighper, nruab nrab hauv H112 Tauj

Kub ua hauj lwm: Pom zoo qhov kub thiab txias300-400 degree

Kev ntxhov siab corrosion tawg: H112 Tem tau ua tau zoo heev rau kev ntxhov siab corrosion tawg

Cryogenic cov khoom: khaws cia lossis txhim kho lub zog thiab tawv ntawm qhov tsis kub tsawg heev

{{07. corrosion Kuj & Kev Tiv Thaiv Cov Tshuab

|

Ib puag ncig hom |

Kev Ntsuas |

Kev Tiv Thaiv Txoj Kev |

Kev cia siab |

|

Muaj cua |

Zoo tshaj |

Huv si |

20+ xyoo |

|

Marine cua |

Zoo tshaj |

Huv si |

15-20+ xyoo |

|

Dej hiav txwv immersion |

Zoo heev |

Cathodic tiv thaiv lossis tha xim |

10-15+} xyoo nrog kev saib xyuas |

|

Siab vaum |

Zoo tshaj |

Huv si |

20+ xyoo |

|

Kev ntxhov siab corrosion |

Zoo heev (H112 Tauj) |

Tsis muaj kev tiv thaiv ntxiv |

Tsis tshua muaj neeg muaj peev xwm |

|

Kho |

Zoo tshaj |

Kev tiv thaiv tus qauv |

Tsis tshua muaj neeg muaj peev xwm |

|

Galvanic corrosion |

Zoo |

Kom muaj kev sib cais |

Ceev faj tsim nrog cov sib luag |

Kev Xaiv deg Nto:

Anodizing:

Hom II (Sulfuric): {10-25 μm thickness, muab kev tiv thaiv thiab kev tiv thaiv ntxiv

Hom III (nyuaj): {25-75 μm tuab, nce hnav tsis kam thiab tawv tawv

Dyeing thiab sealing: txhim kho kom zoo nkauj thiab corrosion tsis kam

Kev hloov dua tshiab txheej:

SROMATE hloov txheej txheem pleev xim (MIL-DTL -5541}}}}}

Kev Xaiv Cov Chromium-Dawb: Ib puag ncig raws li

Lub tshuab tha xim:

Epoxy Primer + Polyurethane Topcoat: muab kev tiv thaiv ntev ntev, tshwj xeeb tshaj yog rau cov ntawv thov marine

{{08. Cov Khoom Siv Rau Lub Cev Rau Cov Kws Tsim Khoom Lag Luam

|

Ntiag tug |

Tus nqi |

Tsim Kev Txiav Txim Siab |

|

Ceev |

2.66 g / cm³ |

Kev Tsim Nyaj Hlav, Qhov Chaw Ntawm Lub Ntiaj Teb Tswj |

|

Melting ntau |

575-635 degree |

Vuam thiab Casting Cov Qauv |

|

Thermal conductivity |

121 W/m·K |

Kev tswj hwm cua sov, kev hloov pauv kub |

|

Hluav Taws Xob Kev Tshaj Tawm |

34% IACS |

Hluav Taws Xob Kev Siv Hluav Taws Xob |

|

Cov cua sov tshwj xeeb |

897 J / Kerg · K |

Thermal Mass thiab cua kub muaj peev xwm |

|

Thermal Expansion (CTE) |

24.0 ×10⁻⁶/K |

Kev hloov sab nraud vim yog qhov kub hloov pauv |

|

Cov tub ntxhais hluas lub modulus |

70.3 GPA |

Deflection thiab stiffness suav |

|

Poisson tus piv |

0.33 |

Cov Txheej Txheem Ntsuam Xyuas Parameter |

|

Damping muaj peev xwm |

Tswj kav |

Kev co thiab suab nrov tswj |

Kev txiav txim siab tsim:

Kev Ua Haujlwm Kub Ntau: {-200℃rau {{}}} Cov qib (ntev-ntev tshaj plaws no yuav ua rau muaj kev puas siab, cuam tshuam rau scc tsis kam)

Cryogenic Performance: tswj hwm lossis txhim kho lub zog thiab tawv ntawm qhov tsis tshua muaj kub, zoo tagnrho rau cov khoom siv cryogenic

Cov khoom sib nqus: tsis sib nqus

Rov ua dua tshiab: 100% siv tau nrog cov nqi siab

Formancion: Zoo hauv O Tauj, ib nrab hauv H112 Tauj

Qhov seem ruaj khov: Zoo seem seem ruaj khov tom qab forging thiab kev ntxhov siab nyem

Lub zog-hnyav piv: Qhov zoo hauv cov ntawv thov kom muaj zog thiab corrosion tsis kam

9. Kev paub tseeb & kev xeem

Cov Qauv Kuaj Cov Txheej Txheem:

Tshuaj lom neeg cov tshuaj:

Optical Opission Spectroscopy

X-Tshav Fluorescence tsom tsom Tsom

Cov ntaub ntawv pov thawj ntawm txhua qhov tseem ceeb thiab cov ntsiab lus los txawv

Kev Kuaj Neeg Kho:

Tensile Testing (radial, tangent, axial)

Kev kuaj Hardness (Brinell, ntau qhov chaw)

Kev Cuam Tshuam Kev Ntsuas (Charpy V-Notch, tshwj xeeb tshaj yog rau cov ntawv thov cryogenic)

Qaug zog xeem (raws li yuav tsum tau)

Nondestructive Testing:

Ultrasonic kev tshuaj xyuas (100% Volumetric, ib astm B594 / E2375, lossis 1130)

Eddy kev sim tam sim no (saum npoo thiab ze-nto tsis xws luag)

Kev kuaj xyuas tob tob (saum npoo tsis xws luag)

TradiGraphic Xeem (Sab Hauv Macroscopic tsis xws luag)

Microstructioning:

Grain Loj Kev Txiav Txim Siab

Nag lossis daus thiab intermetallic compound ntsuam xyuas

Grain flow qauv pov thawj

Kev ntxhov siab corrosion rhiab ntsuas

Tshuaj Ntsuam Xyuas Sab Nrau:

CMM (koom ua ke ntsuas lub tshuab ntsuas)

Txheej txheej uas hla, sab hauv lub taub, phab ntsa tuab, qhov siab, fav txhua yam, thiab lwm yam.

Qauv ntawv pov thawj:

Cov ntaub ntawv xeem ntawv tshaj tawm (en 10204 3.1 lossis 3.2)

Tshuaj Ntsuam Xyuas Tshuaj Txheeb Xyuas

Cov Khoom Siv Neeg Kho Tshuab Cov Khoom Siv

Kev Kho Cua Sov / Forging Daim Ntawv Pov Thawj

Nondestructive Testioning Daim Ntawv Pov Thawj

Conformance rau Astm B247 (Kev Zam Txim), GB / T 3880 (Suav tus qauv), en œ-5083 .

10. Daim ntawv thov & Tsim Kev Txiav Txim

Thawj cov ntawv thov:

Marine Kev Lag Luam:

Nkoj thiab Yacht Siv (Hull Cov Qauv, Cov Khoom Siv Lawj, Dej Hiav Txwv)

Offshore drilling platform tsim txheej txheem

Cov Khoom Siv Desalination

Cheebtsam Submarine

Cryogenic Engineering:

Liquefied nkev (lng) cia tso tsheb hlau luam thiab hloov cov pipeline rings

Cryogenic Khoom Siv Khoom Siv

Siab Hlab:

Nruab nrab rau cov kev siab siab ntawm lub nkoj ntawm cov nplaim hluav taws kub thiab cov nplhaib

Siab-Cov Kabmob Khoom Siv Khoom Siv

Kev Lag Luam Nuclear:

Nuclear Reactor Cua Txias Txheej Txheem

Hluav taws xob tiv thaiv cov qauv

Kev Hloov Hla:

Kev tsheb ciav hlau siab ceev lub cev lub cev muaj zog

Tsim Zoo:

Zoo tshaj plaws corrosion, tshwj xeeb yog nyob hauv ib puag ncig thiab muaj kev muaj chaw, nrog lub siab tiv taus dej hiav txwv corrosion

Superior Weldability, nrog Held Weld Lub Zog thiab Kev Deev Zoo

Tshwj phua lub cryogenic tougness, nrog kev txhim kho cov khoom ntawm qhov kub tsawg heev

Lub zog nruab nrab thiab qhov ductility, haum rau cov txheej txheem sib xyaw

Forging cov txheej txheem offlations grain thiab zoo nyob hauv

Kev tiv thaiv zoo heev rau kev ntxhov siab corrosion tawg thiab exfoliation corrosion

Lub teeb yuag, ua rau muaj kev txuag hluav taws xob thiab emission txo

Tsis muaj hlau nplaum

Kev txwv tsis muaj kev txwv:

Tsis tuaj yeem dag zog los ntawm kev kho cua sov; Qhov hluav taws xob tsawg dua 2xxx thiab 7xxx Series-zog alloys

Kev siv sijhawm ntev txog 65 qib yuav ua rau muaj kev lom zem (vim mg₂al₃

Lub zog yog qis dua 5083's H116 / H321 Tempers, tab sis tej zaum yuav ua tau zoo dua nyob rau hauv tshwj xeeb corrosive ib puag ncig.

Tus nqi siab dua .

Kev Txiav Txim Siab Kev Lag Luam:

Cov Khoom Siv Ua Haujlwm Siab, siab dua tus nqi them tab sis ntev lifespan thiab qib tsis tu ncua

Zoo heev corrosion resistance muaj kev tiv thaiv ntev ntev

Zoo Weldability Lowers Tus Nqi Ntawm Cov Qauv Txheej Txheem Txheej Txheem

Lub teeb yuag yuag yuav pab txo cov nqi roj thauj khoom

Kev Ncaj Ncees:

100% rov siv dua nrog cov peev txheej siab siv tau

Aluminium ntau lawm cov txheej txheem yog ua kom muaj kev nce qib ib puag ncig, nrog kev noj kom tsawg

Lub neej ntev kev pab cuam txo cov kauj vab

Cov Khoom Siv Xaiv Xaiv:

Xaiv 5A06 H112 Forged cov nplhaib thaum lub zog muaj zog, tshwj xeeb rau kev txwv tsis pub muaj), thiab cov kev txwv ntawm lub zog tsis yog li 7075 / {}

Rau cov txheej txheem ua haujlwm ntev ntawm lub sij hawm ntev ntawm 65 degree, H321 yuav tsum raug xaiv, lossis lwm yam alloys tau txiav txim siab.

Haum rau cov ntawv thov tseem ceeb hauv marine, cryuces kev lag luam, thiab kev lag luam nuclear raws li cov txheej txheem thiab siab-cov kabmob-{1}}

Cim npe nrov: 5A06 H112 Txhuas Ntses Forged Ntiv Nplhaib, Tuam Tshoj 5A06 H112 Txhuas Ntses Forged Ntiv Nplhaib Khoom, Cov Chaw Muag Khoom, Hoobkas

Xa kev nug